Search

5G AAU FPC/PCB Design, Material & Production: Key Tips + Huaruixin’s Expert Solutions

- Aug 28,2025

-

Share

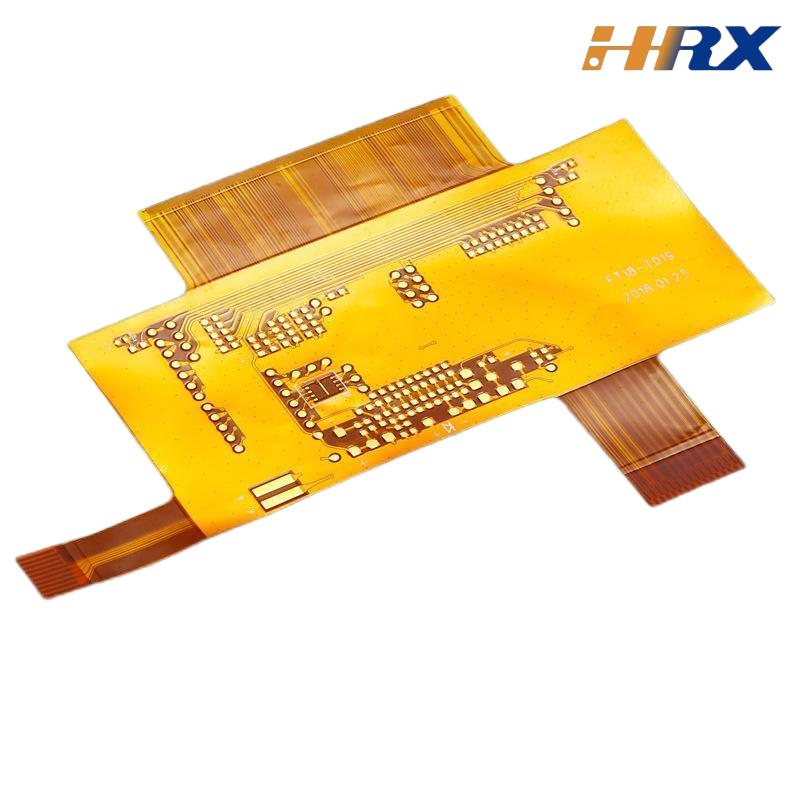

As 5G networks expand globally, the demand for high-performance Active Antenna Units (AAUs) surges— and 5G AAU FPC (Flexible Printed Circuit) and Rigid-Flex PCB for 5G AAU are critical to their success. These components enable compact designs, stable high-frequency signal transmission, and durable operation in harsh environments. However, optimizing 5G AAU printed boards requires precision in material selection, design, manufacturing, and quality control.

Shenzhen Huaruixin Electronics Co., Ltd.—a leading global 5G AAU PCB manufacturer specializing in FPC, PCB, and Rigid-Flex PCB ODM/OEM services—has mastered the challenges of 5G AAU production. This blog breaks down essential considerations for 5G AAU pre-design to packaging, integrates FPC technical terminology, and highlights how Huaruixin delivers industry-leading 5G AAU FPC solutions.

1. Material Selection for 5G AAU FPC/PCB: Prioritize High-Frequency & Flex Durability

5G AAUs operate at sub-6 GHz and mmWave bands, requiring materials that minimize signal loss while withstanding dynamic bending (a core demand for flexible FPC in 5G AAU). Key material criteria include:

High-frequency performance: Low dielectric constant (Dk: 2.8–3.5) and dielectric loss (Df: <0.005) to avoid signal attenuation—critical for mmWave 5G AAU FPC.

Flex fatigue resistance: Materials like LCP (Liquid Crystal Polymer) or adhesive-less PI (Polyimide) films must endure 10,000+ dynamic flexing cycles without conductor cracking.

Thermal stability: High glass transition temperature (Tg ≥ 170°C) and thermal conductivity (≥0.3 W/m·K) to manage heat from RF chips—essential for 5G AAU thermal management PCB.

FPC-specific materials: Quality flexible copper clad laminate (FCCL) (with 0.5–3 oz copper thickness) and coverlay (PI-based, 25–50μm thick) to protect traces from moisture and mechanical damage.

Huaruixin’s Material Expertise for 5G AAU

To meet strict 5G standards, Huaruixin sources premium materials and customizes selections for 5G AAU FPC applications:

High-frequency FPC substrates: Uses LCP FCCL (Dk=3.0, Df=0.002) for mmWave 5G AAUs, ensuring signal integrity up to 40 GHz—ideal for high-frequency FPC for 5G.

Durable flex materials: Adopts adhesive-less PI films (e.g., DuPont Kapton®) for FPCs, offering superior static flexing and dynamic flexing resistance (-55°C to 200°C operating range).

Thermal-enhanced PCBs: Integrates FR-4 substrates with Tg=180–220°C and copper-infilled thermal vias (0.2–0.5mm diameter) to boost heat dissipation for 5G AAU power amplifier PCB.

Quality control for materials: All FCCL, coverlay, and substrates undergo IQC (Incoming Quality Control) testing—including Dk/Df measurement via Agilent network analyzers—to eliminate defective inputs.

2. 5G AAU FPC/PCB Design: Optimize for Signal Integrity & Miniaturization

5G AAUs require compact, integrated designs to fit outdoor/indoor installations—making Rigid-Flex PCB for 5G AAU a game-changer (it replaces separate PCBs and cables, cutting assembly time by 25%). Key design considerations:

Signal integrity (SI) for FPC: Optimize trace routing (50Ω impedance for RF lines) to reduce crosstalk; use differential pairs for high-speed signals and avoid sharp bends (minimum bend radius: 3x FPC thickness) to prevent conductor stress.

Rigid-Flex integration: Combine rigid sections (for component mounting: RF chips, filters) and flexible sections (for folding in tight spaces) to reduce 5G AAU volume by 30%.

DFM (Design for Manufacturability): Ensure FPC designs align with production capabilities—e.g., minimum line width/spacing ≥25μm, coverlay alignment tolerance ≤10μm, and via-in-pad (VIP) for high-density components.

EMI shielding: Integrate copper foils or conductive coatings into FPC/PCB designs to suppress electromagnetic interference (EMI)—critical for 5G AAU RF PCB performance.

Huaruixin’s 5G AAU Design Solutions

As a 5G AAU FPC design ODM, Huaruixin offers end-to-end design support with a focus on performance and manufacturability:

SI/PI simulation: Uses Cadence Allegro and ANSYS HFSS to simulate mmWave signal behavior, optimizing trace length matching (±0.1mm) and impedance control for 5G AAU FPC—reducing signal loss by 15%.

Custom Rigid-Flex designs: Engineers tailor Rigid-Flex PCB for 5G AAU with flexible hinges (1–3mm width) and rigid FR-4 sections (1.6–3.2mm thickness), ensuring compatibility with AAU mechanical structures.

DFM validation: A dedicated team reviews designs pre-production, flagging issues like overly narrow traces or incorrect coverlay opening sizes—avoiding 90% of production delays.

EMI mitigation: Adds grounded copper planes to FPC/PCB layers and uses conductive adhesives for 5G AAU RF PCB, reducing EMI by 20dB.

3. Manufacturing Process for 5G AAU FPC/PCB: Precision & Consistency

5G AAU FPC manufacturing demands ultra-precise processes to ensure batch consistency—even minor defects (e.g., FCCL etching errors) can render AAUs non-functional. Key process controls:

FPC etching: Use laser direct imaging (LDI) for 25μm line width/spacing and alkaline etching to ensure uniform FCCL conductor thickness.

Rigid-Flex lamination: Apply controlled pressure (15–20 kg/cm²) and temperature (180–220°C) to bond rigid and flexible layers, avoiding delamination.

SMT assembly: High-speed placement machines (Yamaha YSM40R) with ±0.03mm accuracy for mounting miniaturized components (e.g., 01005 chips) on 5G AAU PCB.

Plasma cleaning: Treat FPC surfaces with plasma to improve coverlay adhesion and remove contaminants—critical for long-term reliability.

Huaruixin’s Production Capabilities

Huaruixin’s 15,000㎡ manufacturing base is equipped for large-scale, high-precision 5G AAU FPC production:

Advanced FPC equipment: LDI machines (Orbotech Sprint) for fine-line patterning, laser drilling machines (Fujitsu) for 50μm microvias, and plasma cleaners (Plasmatreat) for surface preparation.

SMT excellence: 10+ SMT lines with AOI (Automatic Optical Inspection) and SPI (Solder Paste Inspection) systems to detect 99% of assembly defects (e.g., missing components, solder bridges).

Rigid-Flex production: Custom lamination presses and laser cutting machines to ensure precise bonding of rigid and flexible layers—yield rate ≥98% for Rigid-Flex PCB for 5G AAU.

Environmental control: Class 1000 cleanrooms with 23±2°C temperature and 45±5% humidity to prevent dust from affecting 5G AAU FPC quality.

4. Quality Control (QC) for 5G AAU FPC/PCB: Rigorous Testing

5G AAUs operate 24/7 in harsh conditions—so 5G AAU PCB QC must validate performance, durability, and reliability. Key tests:

Electrical testing: Flying probe testing for continuity, insulation resistance (≥10^10Ω), and impedance (50Ω ±10%) of 5G AAU FPC.

Mechanical testing: Flex testing (10,000 cycles at 180° bending) for FPCs, thermal cycling (-40°C to 85°C, 1,000 cycles) to check for delamination.

Environmental testing: Humidity testing (85% RH, 85°C, 1,000h) and salt spray testing (5% NaCl, 48h) to validate corrosion resistance.

Huaruixin’s QC System

Huaruixin follows ISO 9001, IATF , and IPC standards for 5G AAU FPC QC:

In-process testing: IPQC inspectors check every production stage—from FCCL etching to coverlay lamination—using calibrated tools (e.g., digital microscopes).

Final testing: 100% electrical testing via flying probes, 10% sampling for mechanical/environmental tests, and X-ray inspection for hidden defects (e.g., via voids).

Traceability: Each board has a unique serial number, tracking materials, production steps, and test results—critical for 5G AAU PCB compliance and troubleshooting.

5. 5G AAU FPC/PCB Packaging: Protect During Global Shipping

5G AAU FPC is sensitive to ESD (Electrostatic Discharge) and moisture—packaging must safeguard against damage:

ESD protection: Anti-static bags (surface resistance 10^6–10^11Ω) and conductive foam.

Moisture barrier: Vacuum-sealed aluminum foil bags with desiccants (RH ≤30%).

Shock absorption: Corrugated cartons with foam inserts (meets ISTA 3A standards).

Huaruixin’s Packaging Solutions

For global shipments, Huaruixin customizes packaging for 5G AAU FPC/PCB:

ESD-safe packaging: Anti-static bags with ESD labels and warning signs.

Moisture control: Desiccants (1–5g per bag) and humidity indicator cards to monitor RH.

Labeling: Clear labels with batch number, quantity, storage conditions (e.g., “Store at 10–30°C”), and RoHS/REACH compliance marks—easing customs clearance.

Partner with Huaruixin for Your 5G AAU FPC/PCB Needs

Whether you need high-frequency FPC for 5G, Rigid-Flex PCB for 5G AAU, or full ODM/OEM services, Huaruixin delivers:

Expertise: 10+ years in 5G AAU FPC design and manufacturing, with engineers specializing in mmWave and high-frequency applications.

Speed: Prototype lead time 7–10 days, mass production 2–4 weeks.

Quality: Yield rate ≥98%, 0-defect shipping guarantee.

Get in touch today:

Learn more:www.hrxfpc.com (5G AAU FPC/PCB case studies & technical resources)

Consult our team:sales@hrxfpc.com (request quotes or technical support for 5G AAU PCB projects)

Huaruixin—your trusted 5G AAU FPC manufacturer for reliable, high-performance 5G infrastructure!

FAQ

1.Which FPC material is best for 5G AAU?

LCP (Liquid Crystal Polymer) FCCL is ideal—it offers low Dk/Df for mmWave signals and excellent flex fatigue resistance.

2.What is the minimum line width for 5G AAU FPC?

Huaruixin achieves 25μm line width/spacing for 5G AAU FPC using LDI technology.

3.How to ensure 5G AAU PCB signal integrity?

Optimize trace routing (50Ω impedance), use differential pairs, and simulate SI with tools like ANSYS HFSS—Huaruixin’s design team specializes in this.

Let’s talk! We’ll provide the perfect solution for you!

-

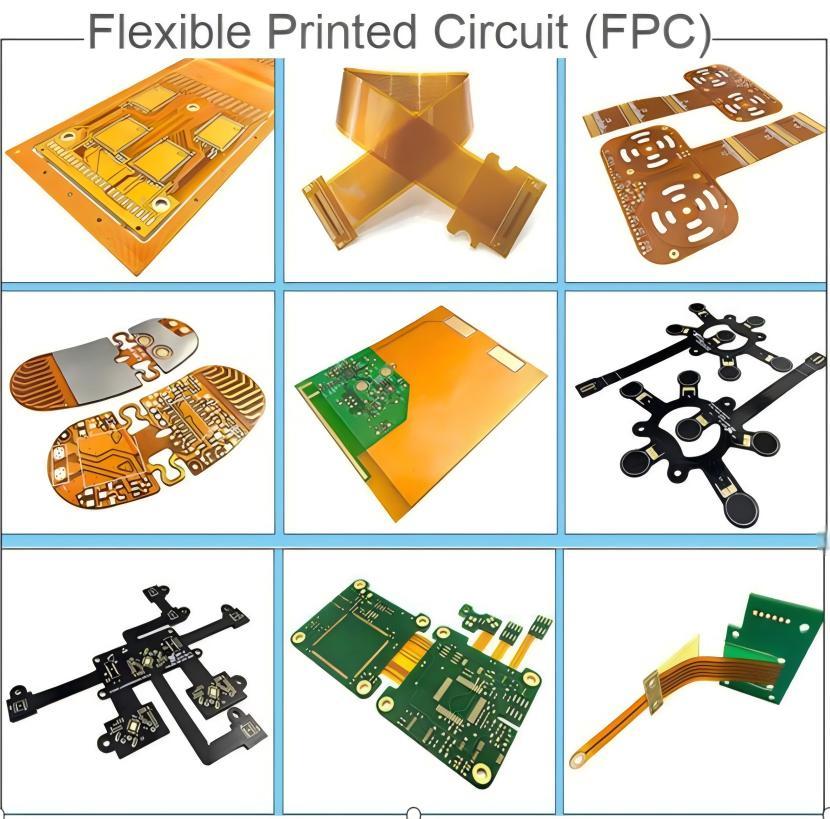

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP