Search

3D Stereo Integration Innovation in FPC Design: Revolutionizing Wearable & Automotive Electronics

- Mar 19,2025

-

Share

By Shenzhen Huaruixin Electronics Co., Ltd. – Your Trusted Partner in Advanced FPC/PCB/Rigid-Flex Solutions

Introduction: The Era of 3D Stereo Integration in FPC Design

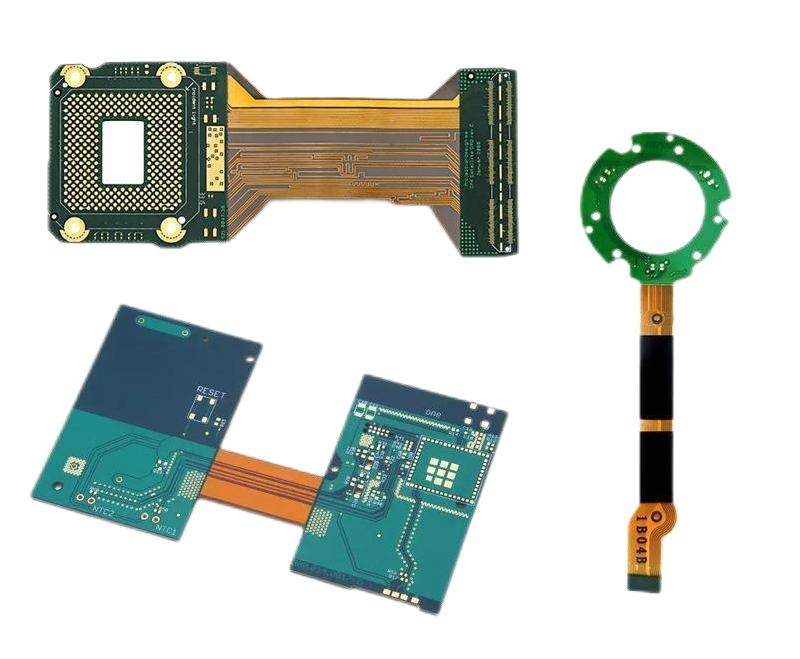

In 2025, the convergence of miniaturization, functional density, and reliability demands is driving a paradigm shift in flexible printed circuit (FPC) design. At Shenzhen Huaruixin Electronics, we specialize in transforming complex spatial challenges into innovative 3D stereo integration solutions. This technical deep dive explores two groundbreaking use cases—wearable devices and automotive electronics—where our FPC expertise, combined with strategic partnerships, is redefining industry standards.

Case 1: Wearable Devices – Next-Gen Smartwatch Platform (Leading Wearable Brand Collaboration)

Challenge: Integrating 12 sensors into a 46mm smartwatch form factor while optimizing power efficiency and thermal management.

Innovation: Annular FPC + Custom-Shaped Battery architecture by Huaruixin’s Advanced Design Team.

Huaruixin’s Contribution:

3D Topology Design: Developed an annular FPC (360° circumferential layout) to envelope the custom-shaped battery, enabling omni-directional sensor placement and eliminating planar constraints.

Space Optimization: Leveraged rigid-flex technology with micro-vias (0.1mm via diameter) and stacked-layer routing to achieve 35% space savings vs. traditional 2D layouts.

Material Engineering: High-temperature polyimide (PI) substrates (UL 94 V-0 rating) with embedded EMI shielding (30dB attenuation @ 1-10GHz) ensured thermal stability (<15°C rise under continuous operation) and signal integrity.

Technical Insight:

Wearable FPC design requires a triad of miniaturization, thermal regulation, and modularity. Our 3D FPCs employ functional zoning—segregating power (2A-rated traces), high-speed signals (MIPI/USB 3.2), and sensor interfaces (bio-potential amplifiers) to mitigate crosstalk. Example: Embedded inductive charging coils (15W wireless power) within the FPC’s layered structure (2oz Cu, 50μm dielectric) eliminated discrete components, reducing BOM count by 12%.

Industry Trend: Wearables are evolving into body-area networks (BANs). Future FPCs will integrate conformal sensors (PPG/ECG), 5G antennas (patterned via arrays), and energy harvesting modules (thermoelectric generators) using AI-driven design tools (ANSYS Twin Builder) for real-time thermal-electric co-simulation.

Case 2: Automotive Electronics – CTC Battery System (Premier Electric Vehicle Manufacturer Collaboration)

Challenge: Enhancing energy density (Wh/L), reducing weight (kg/kWh), and improving safety in cell-to-chassis (CTC) battery platforms.

Innovation: FPC-Based Smart Interconnect System replacing traditional wiring harnesses in a next-gen CTC architecture.

Huaruixin’s Contribution:

Structural Integration: Multi-layer FPCs (8 layers, 0.3mm thickness) replaced 15kg of copper harnesses, creating a load-bearing electrical backbone (50MPa tensile strength) between 4680-type cells and the chassis.

Performance Optimization: Integrated temperature sensors (±0.5°C accuracy), busbars (500A continuous rating), and cell balancing circuits to achieve 8% energy density improvement and 20% faster thermal response (ΔT < 2°C/min).

Reliability Engineering: Automotive-grade FPCs (IATF 16949 certified) with IP69K waterproofing (10bar pressure, 85°C), flame-retardant materials (UL 94 V-0), and 10G vibration resistance (ISO 16750) met ASIL-D safety standards.

Technical Insight:

Automotive FPCs require system-level redundancy—serving as both electrical pathways and structural components. In the CTC platform, the FPC acts as a crash-resistant interposer (5mm crush tolerance), reducing solder joints by 70% (via laser soldering technology) and eliminating failure points. Embedded impedance sensors enable predictive maintenance (cell degradation detection: <0.1mΩ resolution).

Industry Trend: The automotive sector is shifting to electronics-first chassis design. FPCs will dominate next-gen 800V systems, enabling direct cell-to-module communication (CAN FD 5Mbps) and real-time health monitoring via AI-edge processing (on-board FPC-mounted microcontrollers).

Huaruixin’s 3D FPC Design Framework: Beyond 2D Constraints

Our 3D stereo integration philosophy is built on three pillars:

Topology Optimization: AI-driven tools (ANSYS SIwave, CST Studio) for 3D thermal-electric co-simulation (ΔT < 5°C, EMI < -40dB).

Material Agility: Custom substrates (low-CTE PI: 15ppm/°C, LCP for high-frequency applications) tailored for -55°C to +125°C operational ranges.

Manufacturing Precision: 0.03mm line/space resolution (LDI technology), 3D automated optical inspection (AOI), and laser direct structuring (LDS) for micron-level accuracy.

Unique Value Propositions:

DFM Collaboration: Early-stage co-development via our virtual prototyping platform (VR-based 3D FPC modeling).

Testing Regime: In-house thermal cycling (1,000 cycles: -40°C to +125°C), high-pot testing (5kV), and X-ray inspection (5μm resolution) ensuring 99.99% yield.

Why Partner with Huaruixin?

Legacy & Expertise: 20+ years in FPC/PCB/rigid-flex innovation, supporting Fortune 500 clients in wearables, automotive, and aerospace.

End-to-End Solutions: From concept (via our DFM portal) to mass production including post-sales failure analysis (FA) support.

Sustainability: Green manufacturing (lead-free, RoHS 2.0 compliant) and recycled materials (30% post-consumer content in substrates).

Join the 3D Integration Revolution

Whether developing next-gen wearables or electrified vehicles, Huaruixin’s 3D FPCs transform spatial challenges into competitive advantages.

Contact Us: sales@hrxfpc.com

Explore Solutions: www.hrxfpc.com

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP