Search

The Role of Serpentine Traces in FPC Boards

- May 12,2025

-

Share

In the sophisticated realm of Flexible Printed Circuit (FPC) boards, serpentine traces are indispensable elements that wield a profound influence on the performance, reliability, and signal integrity of electronic devices. As a preeminent global ODM/OEM manufacturer specializing in the design, development, and large-scale production of FPC, PCB, and Rigid-Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. possesses unparalleled expertise in leveraging the potential of serpentine traces.

Signal Delay Compensation and Timing Alignment

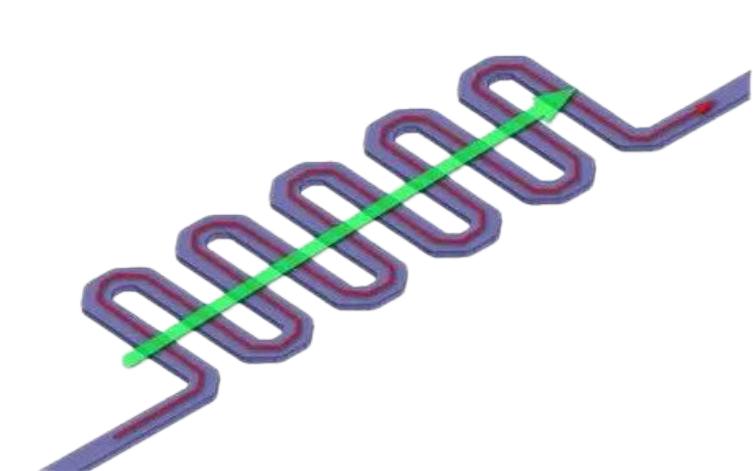

One of the fundamental functions of serpentine traces lies in signal delay compensation, a crucial aspect of maintaining proper timing alignment in FPC circuits. In high - speed digital systems, when high - frequency signals traverse traces on an FPC board, inherent signal propagation delays occur due to factors such as trace length, characteristic impedance, and dielectric properties. Serpentine traces are carefully engineered to compensate for the shorter delays in “related groups” of signal lines, typically those that undergo minimal or no additional logical processing. A classic example is the clock signal lines, which often bypass complex logic gates and thus experience relatively shorter delays compared to other associated data or control signals.

At Shenzhen Huaruixin Electronics, our team of seasoned engineers employs advanced signal integrity analysis tools to precisely calculate and design serpentine traces. By adjusting the length and geometry of these traces, we ensure that the signal delays within a group are meticulously balanced, thereby guaranteeing accurate data transmission and synchronization. This meticulous approach to signal delay compensation is essential for maintaining the overall performance and functionality of high - speed digital systems.

Equal Trace Length Design for High - Speed Digital FPC Boards

In high - speed digital FPC board design, maintaining equal trace lengths for critical signal nets is of utmost importance. This practice is primarily aimed at ensuring that the delay differences between various signals remain within an acceptable tolerance range, which is crucial for the valid readout of data within the same clock cycle. As a general rule, the allowable delay difference is typically specified as no more than 1/4 of a clock cycle. Exceeding this limit can lead to data setup and hold time violations, resulting in incorrect data readings and system malfunctions.

The delay per unit length of a trace is influenced by multiple parameters, including line width, line length, copper thickness, dielectric constant of the substrate material, and board layer stack - up. However, it's important to note that excessively long traces can introduce significant distributed capacitance and inductance, which can severely degrade signal quality by causing signal reflections, crosstalk, and attenuation. To mitigate these issues, our company often implements techniques such as impedance control, proper termination (e.g., RC termination at the pins of clock ICs), and strategic placement of vias during the design process.

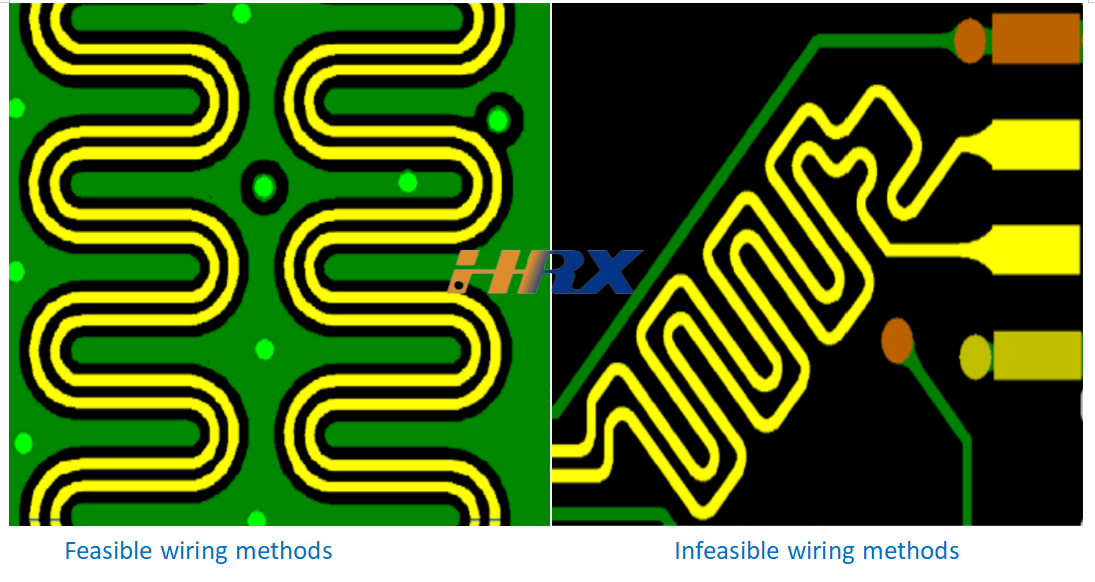

It's a common misconception that serpentine traces are used to add inductance. In fact, unwanted inductance can cause phase shifts in the higher harmonics of the signal's rising edge, leading to signal distortion and degradation of signal integrity. To minimize these effects, we strictly adhere to the design guideline that the spacing between serpentine traces should be at least twice the line width. Additionally, careful consideration is given to the signal rise time, as faster - rising signals are more susceptible to the adverse effects of distributed capacitance and inductance.

Application - Specific Roles of Serpentine Traces

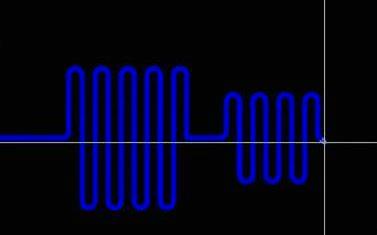

The role of serpentine traces can vary significantly depending on the application scenario. In computer boards, serpentine traces often serve as effective filtering inductors, enhancing the circuit's immunity to electromagnetic interference (EMI) and radio - frequency interference (RFI). In clock signals such as CIClk and AGPClk, they perform a dual function of impedance matching and filtering, ensuring stable and reliable clock signal transmission.

For critical high - speed signal nets like HUBLink in the INTEL HUB architecture, which operates at 233MHz and consists of 13 differential signal pairs, strict equal - length requirements must be met to eliminate potential timing hazards caused by signal skew. Serpentine routing is often the most practical solution to achieve the necessary trace length matching while adhering to the board's physical constraints. Similarly, on PCI boards, serpentine traces are utilized to meet the specific line length requirements for the 33MHz PCI clock signal, ensuring proper bus operation and data transfer.

In general - purpose PCB boards, serpentine traces can function as distributed - parameter LC filters, and in some specialized applications, they can even be configured as inductor coils for radio antennas or as fuses when designed with appropriate geometries and dimensions.

Shenzhen Huaruixin Electronics: Your Partner in FPC Design and Manufacturing

With decades of experience in the printed circuit board industry, Shenzhen Huaruixin Electronics Co., Ltd. has successfully applied these advanced design principles in numerous projects, delivering high - quality FPC boards that meet the most stringent requirements of our global clients. We understand that each project is unique, with its own set of design challenges and performance requirements. Our team of experts, including electrical engineers, PCB designers, and signal integrity specialists, is committed to providing customized solutions that address every aspect of FPC design, from serpentine trace optimization to overall board layout and manufacturing.

If you're interested in learning more about our FPC products and services, or if you have specific technical questions regarding serpentine trace design and FPC development, we invite you to visit our website at www.hrxfpc.com. You can also reach out to us via email at sales@hrxfpc.com. We look forward to engaging in technical exchanges, sharing our expertise, and collaborating with you on your next FPC project. Together, let's explore the cutting - edge possibilities in the field of printed circuit board technology.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP