Search

Mastering FPC Impedance Design: Advanced Insights and Best Practices

- May 09,2025

-

Share

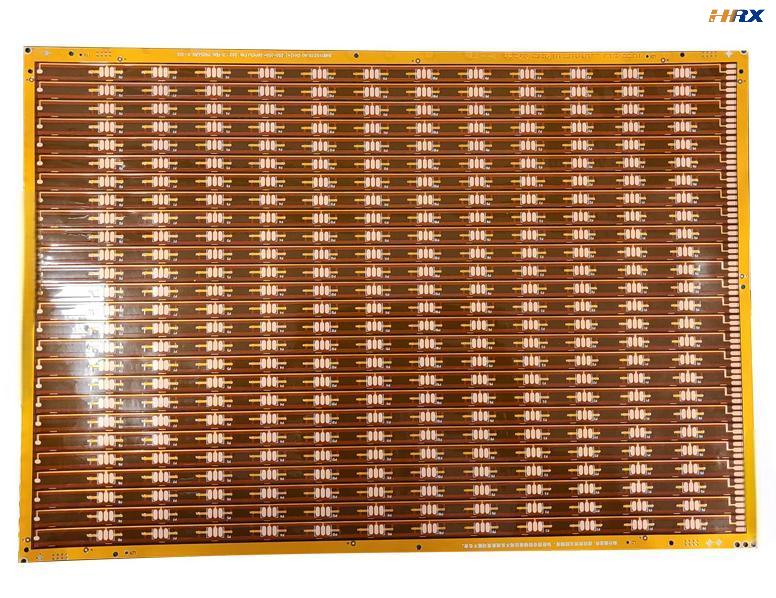

In the rapidly evolving realm of electronics manufacturing, Flexible Printed Circuits (FPCs) have become indispensable for compact, high-performance device designs. As a premier global ODM/OEM manufacturer specializing in FPC, PCB, and Rigid-Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. combines cutting-edge design capabilities with state-of-the-art large-scale manufacturing facilities. Our deep expertise in FPC impedance design, a critical aspect of high-speed circuit development, stems from years of serving diverse sectors worldwide.

The Imperative of FPC Impedance Control

In high-frequency and high-speed digital applications, impedance control in FPCs is non-negotiable for ensuring signal integrity, minimizing attenuation, and mitigating electromagnetic interference (EMI). Deviations from the target impedance can result in signal reflections, crosstalk, and significant performance degradation, especially in applications such as 5G communication, automotive electronics, and aerospace systems. At Shenzhen Huaruixin Electronics, our holistic approach to FPC design places impedance optimization at the core, leveraging advanced simulation tools and stringent quality control processes.

Fundamental Parameters: Line Width and Line Spacing

Line Width Optimization

The line width of FPC traces is a primary determinant of impedance, influenced by multiple factors including substrate material (e.g., polyimide), dielectric constant (εr), and copper foil thickness. For single-ended traces on a standard FR-4 substrate (εr ≈ 4.4) with 1 oz copper, achieving a 50-ohm impedance typically requires a line width of 8 - 10 mils. In contrast, differential pairs aiming for 100-ohm impedance often utilize 5 - 6 mil-wide traces, meticulously calculated to meet impedance requirements.

| Impedance Target | Trace Configuration | Line Width (mils) | Substrate Material | Dielectric Constant (εr) | Copper Thickness |

50 Ω (Single-ended) | Single-ended | 8 - 10 | FR-4 | 4.4 | 1 oz |

100 Ω (Differential) | Differential Pair | 5 - 6 | FR-4 | 4.4 | 1 oz |

In high-speed FPCs, the skin effect at elevated frequencies necessitates careful consideration. As frequency increases, current concentrates near the conductor surface, effectively reducing the conductive cross-section. To counteract impedance variations, engineers may adjust line width, often increasing it slightly to maintain consistent impedance performance.

Line Spacing Considerations

Line spacing, the distance between adjacent traces, is crucial for impedance stability and crosstalk prevention. A minimum spacing equal to the line width is a common baseline for basic impedance control. However, for high-density FPCs operating at high frequencies, a spacing of 1.5 - 2 times the line width is recommended to minimize electromagnetic coupling and enhance signal isolation.

Design Context | Recommended Line Spacing (relative to line width) |

General-purpose FPCs | 1:1 |

High-speed, high-density FPCs | 1.5 - 2 |

Advanced FPC Design Techniques

Our design engineers at Shenzhen Huaruixin Electronics employ a multi-faceted approach, integrating advanced design for manufacturability (DFM) principles and electromagnetic field simulations. Tools like Ansys HFSS and Cadence Allegro enable precise impedance modeling, accounting for factors such as dielectric thickness, trace length, and via structures. Rigorous in-process testing, including time-domain reflectometry (TDR) and vector network analysis (VNA), ensures that every FPC meets strict impedance tolerances.

Connect with Shenzhen Huaruixin Electronics

For professionals seeking expert FPC impedance design solutions or industry insights, we invite you to connect with us. Explore our comprehensive range of FPC, PCB, and Rigid-Flex Printed Board offerings at www.hrxfpc.com. To discuss your project requirements or collaborate on innovative designs, contact our technical sales team at sales@hrxfpc.com. Let’s leverage our collective expertise to drive advancements in FPC technology.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP