Search

Key Factors in FPC Material Selection: Ensuring High-Reliability Design and Performance

- Jun 10,2025

-

Share

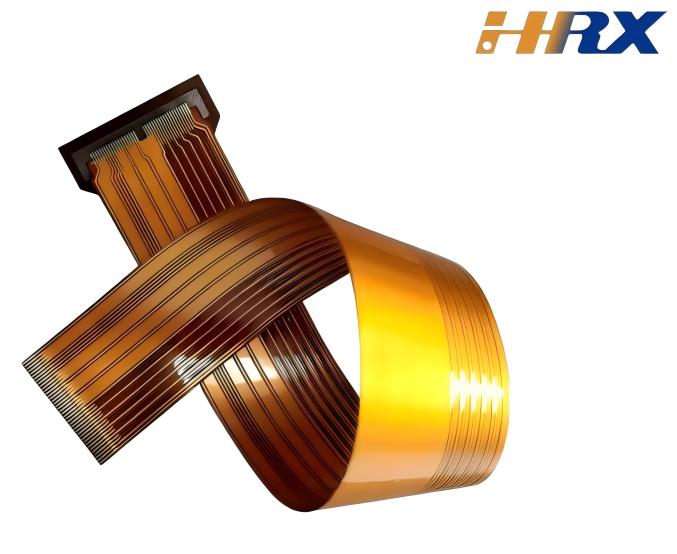

In the rapidly evolving landscape of modern electronics manufacturing, the meticulous selection of materials for Flexible Printed Circuits (FPCs) is not merely a design consideration but a critical determinant of product reliability, performance, and longevity. As a leading global ODM/OEM manufacturer specializing in FPCs, PCBs, and Rigid-Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. leverages decades of industry expertise to navigate the complex interplay of technical requirements, manufacturing constraints, and market demands.

Electrical Performance: The Bedrock of Signal Integrity

Dielectric and Insulation Characteristics

For high-frequency FPC applications, materials with low dielectric constant (Dk) and dissipation factor (Df) are paramount. Polyimide-based laminates with Dk values below 3.5, such as Rogers RT/duroid series, are commonly employed in 5G antenna modules to minimize signal attenuation and crosstalk. Shenzhen Huaruixin's advanced design simulations utilize electromagnetic field solvers to predict insertion loss (IL) and return loss (RL), ensuring optimal material selection for impedance-matched transmission lines. Our custom-designed 5G FPCs, featuring Rogers 4350B substrates, achieve an IL of <0.5 dB/cm at 28 GHz, meeting the stringent requirements of mmWave communication systems.

Conductive Layer Optimization

The choice between electrodeposited (ED) and rolled annealed (RA) copper foils hinges on application-specific needs. ED foils, with a typical surface roughness of Rz < 2 μm, enable fine-line patterning down to 25/25 μm line/space, making them ideal for high-density interconnect (HDI) FPCs. Conversely, RA foils offer superior flexural fatigue life, crucial for dynamic flex applications. Huaruixin's proprietary electroless nickel immersion gold (ENIG) surface finish provides a contact resistance of < 3 mΩ, ensuring reliable electrical connections in medical implantable devices.

Mechanical Durability: Withstanding Dynamic Stress

Flexibility and Fatigue Resistance

The flexural endurance of FPCs is quantified by the number of cycles to failure (NCF) under specified bending radius (R) and angle (θ). For wearable devices requiring continuous flexion, Huaruixin's ultra-thin PI films (12.5 μm) paired with micro-etched copper foils achieve an NCF of > 1 million cycles at R = 1.5 mm. Our patented stress-relief vias and scallop-free etching technology minimize mechanical stress concentration, extending the service life of dynamic flex circuits.

Rigid-Flex Integration

In Rigid-Flex PCBs, the transition zones between rigid and flexible sections demand precise material engineering. Huaruixin's stepped-lamination process, utilizing FR-4 rigid layers and adhesive-bonded PI flex regions, ensures a peel strength of > 6 N/cm, preventing delamination under thermal cycling. Our application of blind/buried vias (BBVs) in Rigid-Flex designs reduces overall thickness by 30%, enabling compact integration in aerospace avionics systems.

Environmental Resilience: Operating in Extreme Conditions

Thermal Management

Materials must exhibit high glass transition temperature (Tg) and low coefficient of thermal expansion (CTE). Huaruixin's high-Tg polyimide films (Tg > 280°C) and ceramic-filled prepregs ensure dimensional stability during reflow soldering (260°C peak) and long-term operation in automotive engine compartments (150°C continuous). Our thermal vias, filled with silver epoxy, enhance heat dissipation, reducing hotspots by 20%.

Chemical and Moisture Resistance

Medical-grade FPCs require biocompatible materials compliant with ISO 10993 standards. Huaruixin's silicone encapsulation and Parylene C coating provide excellent resistance to disinfectants and body fluids, with a water absorption rate of < 0.1%. For marine applications, our fluoropolymer-coated FPCs achieve a salt fog resistance of 1000 hours per ASTM B117.

Manufacturing Compatibility: Enabling Precision Fabrication

Lamination Processability

The CTE mismatch between layers can cause registration errors during lamination. Huaruixin's in-house developed adhesive films with a CTE gradient design minimize thermal stress, achieving an alignment accuracy of ± 30 μm for 8-layer FPCs. Our use of laser direct imaging (LDI) technology enables fine-feature patterning with a sidewall angle of 88°, reducing etching bias.

Cost-Effective Material Selection

Through our extensive material database, we optimize cost-performance ratios for different applications. For consumer electronics, a combination of 1/3 oz ED copper and 25 μm PI can reduce material costs by 20% without sacrificing basic flex performance. Our value engineering approach balances price, performance, and production volume, ensuring competitive solutions for mass-market products.

Regulatory Compliance: Global Market Access

All materials sourced by Shenzhen Huaruixin adhere to RoHS 3.0 and REACH SVHC regulations. Our automotive products are certified to IATF 16949 and AEC-Q200, while medical FPCs comply with FDA 21 CFR Part 820. These certifications streamline market entry for customers across diverse industries.

In conclusion, the selection of materials for FPCs is a multidisciplinary challenge requiring expertise in materials science, electrical engineering, and manufacturing processes. As a trusted partner for high-reliability FPC solutions, Shenzhen Huaruixin Electronics Co., Ltd. offers end-to-end material selection services, from initial design consultation to mass production. For custom FPC, PCB, or Rigid-Flex projects, visit our website www.hrxfpc.com or contact our engineering team at sales@hrxfpc.com. Let us collaborate to transform your innovative ideas into reliable, high-performance electronic products.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP