Search

Key Considerations in the Design and Production of FPCs for Batteries: Unveiling Industry Expertise

- Jun 05,2025

-

Share

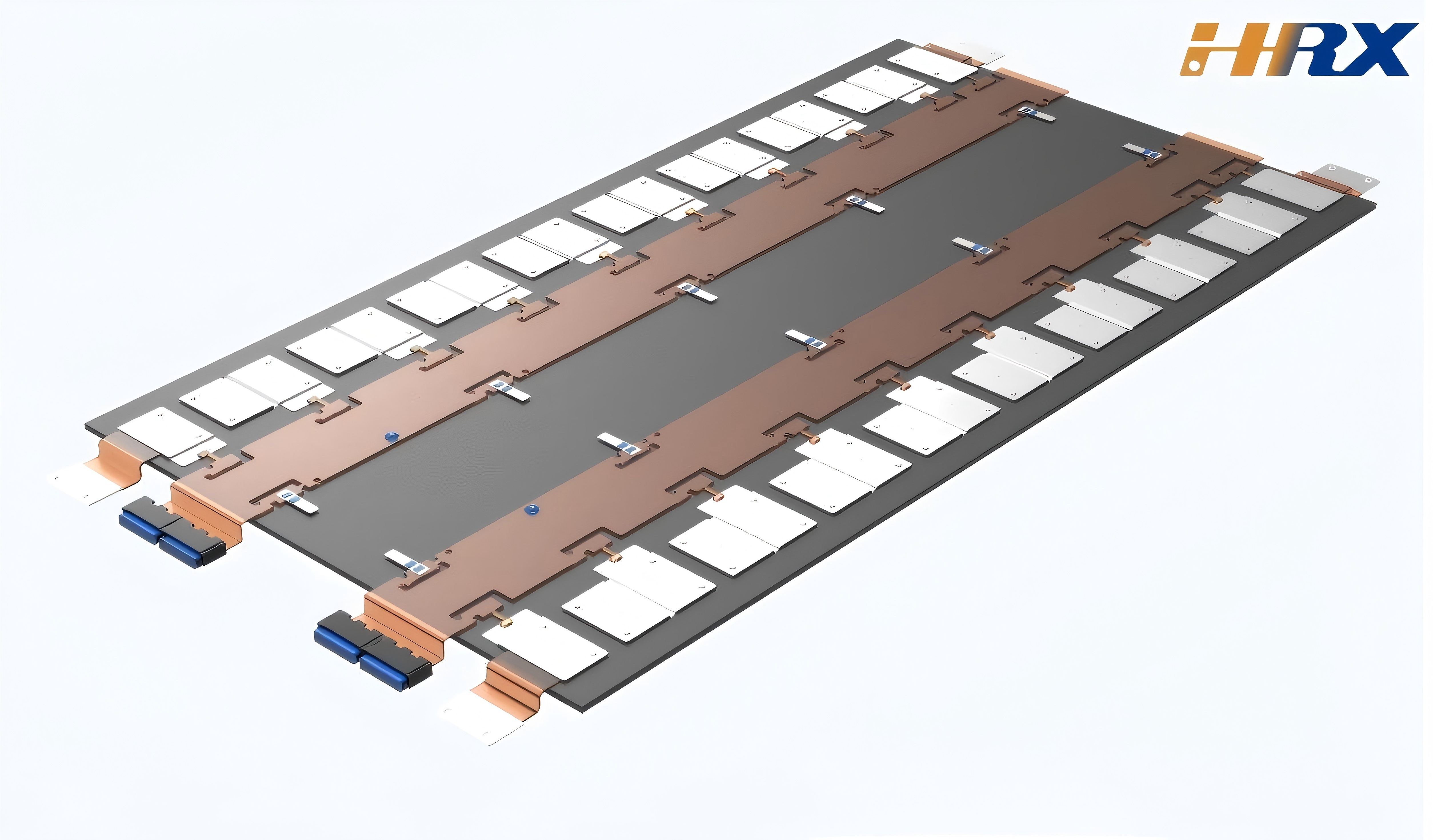

In the rapidly evolving landscape of battery technology, Flexible Printed Circuits (FPCs) have become indispensable components, especially for Battery Management Systems (BMS). These systems rely on FPCs to monitor and control battery performance, ensuring safety and efficiency. Shenzhen Huaruixin Electronics Co., Ltd., a leading global ODM/OEM manufacturer specializing in FPCs, PCBs, and Rigid-Flex Printed Boards, stands out with its cutting-edge design capabilities and large-scale manufacturing facilities.

1. Electrical Performance Optimization: The Core of FPC Design

For FPCs in battery applications, electrical performance is non-negotiable. Key elements include the use of advanced conductive materials and precise circuit design. High-purity copper with low resistivity is commonly used for traces to minimize power loss, while impedance matching ensures stable signal transmission. At Shenzhen Huaruixin Electronics, we leverage our expertise in High-Density Interconnect (HDI) technology to create compact yet highly efficient FPC layouts. Our designers use advanced Electronic Design Automation (EDA) tools to simulate electrical performance, reducing the risk of electromagnetic interference (EMI) and crosstalk. Rigorous in - process testing, such as in - circuit testing (ICT) and flying probe testing, guarantees that each FPC meets the stringent requirements of battery systems.

2. Mechanical Flexibility and Durability: Balancing Act for Long - Term Reliability

The flexibility of FPCs enables innovative battery pack designs, but it must be paired with durability. Our company specializes in developing FPCs with optimized bend radii and cycle life. By using Polyimide (PI) as the base substrate, known for its excellent mechanical properties and thermal stability, we ensure that FPCs can withstand repeated flexing without delamination or trace breakage. Additionally, we incorporate stress - relief structures, such as rounded corners and tapered traces, to distribute mechanical stress evenly. Through Flex Fatigue Testing, we validate the FPCs' ability to endure thousands of bending cycles, a critical factor for the long - term reliability of battery - powered devices.

3. Thermal Management: Keeping Batteries in the Optimal Temperature Range

Effective thermal management is crucial for battery safety and lifespan, and FPCs play a significant role. We design FPCs with integrated thermal vias and thermal interface materials (TIMs). Thermal vias, which are plated - through holes filled with high - thermal - conductivity materials, facilitate heat transfer from hotspots to the battery pack's heat sink. TIMs, such as thermally conductive adhesives, ensure efficient heat dissipation between the FPC and other components. Our expertise in thermal simulation allows us to optimize the FPC layout for maximum heat dissipation, preventing overheating and extending the battery's operational life.

4. Environmental Resistance: Withstanding Harsh Conditions

Batteries are often exposed to challenging environments, including high humidity, extreme temperatures, and vibrations. FPCs must be designed to resist these factors. At Shenzhen Huaruixin Electronics, we apply Conformal Coatings, such as acrylic, urethane, or silicone, to protect FPCs from moisture, dust, and chemicals. These coatings also enhance mechanical protection against abrasion and impact. For applications in high - vibration environments, we use encapsulation techniques to secure components and prevent loose connections. Our FPCs undergo Environmental Stress Screening (ESS) tests, including temperature cycling and humidity testing, to ensure they can perform reliably in various conditions.

5. Design for Manufacturability (DFM): Ensuring Cost - Effective Production

DFM is a fundamental principle in our FPC design process. By considering manufacturing constraints from the start, we can streamline production and reduce costs. We use standard - sized materials and simplify the assembly process, minimizing the need for complex manufacturing steps. Our in - house manufacturing capabilities, including automated pick - and - place machines and advanced soldering techniques, ensure high - quality production at scale. By optimizing the FPC design for manufacturability, we can deliver products faster without sacrificing quality.

In conclusion, the design and production of FPCs for batteries demand a comprehensive understanding of electrical, mechanical, thermal, and environmental factors. Shenzhen Huaruixin Electronics Co., Ltd., with its deep industry knowledge, advanced design tools, and large - scale manufacturing base, is well - equipped to meet the diverse needs of battery FPC applications. Whether it's for electric vehicles, energy storage systems, or portable electronics, our FPC solutions are designed to enhance performance and reliability.

If you have any project requirements or would like to learn more about our FPC products and services, please feel free to contact us. Visit our website at www.hrxfpc.com or email us at sales@hrxfpc.com. We look forward to collaborating with you and providing customized FPC solutions for your battery - related projects.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP