Search

Influencing Factors of FPC Life: Key Insights for Design Optimization

- May 12,2025

-

Share

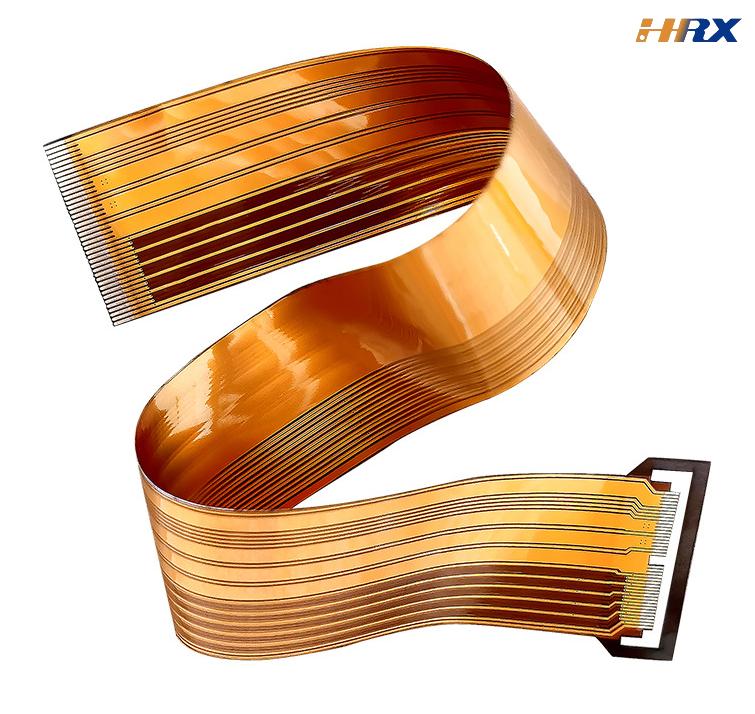

In the realm of advanced electronics manufacturing, Flexible Printed Circuits (FPCs) have emerged as a cornerstone technology, especially in compact devices like smartphones and wearables. Their ability to conform to complex geometries and endure repeated flexing makes them invaluable. However, ensuring the long - term reliability and lifespan of FPCs is a multifaceted challenge. As a global leader in the design, development, and large - scale production of FPCs, PCBs, and Rigid - Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. leverages its extensive expertise to shed light on the critical factors influencing FPC longevity.

1. Design - related Factors

Length and Flexibility Engineering

The design of FPC length is a nuanced process. Unlike rigid printed circuit boards, FPCs offer the advantage of incorporating excess length, reducing the need for hyper - precise initial measurements. At Shenzhen Huaruixin Electronics Co., Ltd., we adopt a data - driven approach. In cases where the initial design length is found to be excessive, our engineers conduct comprehensive folding experiments using advanced testing equipment. Based on the results of these experiments, which analyze parameters like strain distribution and fatigue resistance, we gradually optimize the length to achieve the best balance between flexibility and durability.

Pin Configuration and Layer Optimization

When dealing with a high pin count, designers face the dilemma of width management. One option is to increase the FPC width, but this may not be feasible due to size constraints in modern devices. An alternative approach is to transition from single - sided to double - sided or multi - layer FPCs. However, this comes with the trade - off of increased thickness. Regarding pin line width and pitch, our company has mastered the art of miniaturization. With state - of - the - art manufacturing facilities, we can achieve a minimum line width and pitch of 0.1mm, enabling high - density interconnections. This precision is crucial for enhancing the overall performance and lifespan of FPCs, as it reduces electrical resistance and crosstalk.

Geometric Constraints in Mobile Devices

In mobile phone applications, the dimensions of FPCs are tightly restricted by various factors, including the overall device thickness, hinge mechanics, and the layout of B/C component through - holes. Typically, FPCs are designed with a width of 3mm or 3.5mm. For a 3.5mm - wide FPC, with a standard line width and spacing of 0.1mm each, and a 0.4mm margin from edge traces to the FPC edge, approximately 13 signal lines can be accommodated per layer. The thickness usually ranges from 0.2mm to 0.3mm, depending on the layer structure (2 + 2 or 3 + 2), which impacts the FPC's flexibility and mechanical strength.

2. Mechanical and Environmental Factors

Clearance and Compatibility Design

The interaction between the FPC and surrounding components, particularly B/C parts and through - holes, is a critical aspect of design. At Shenzhen Huaruixin Electronics Co., Ltd., we consider this area as a focal point for optimization. When the wall thickness and strength of B/C components are sufficient, we prioritize creating ample space for the FPC. Since the FPC undergoes repetitive flexing during the opening and closing of mobile phone flips, and given its susceptibility to mechanical damage, the risk of abrasion against the housing is high. This abrasion not only generates audible noise but also leads to progressive damage, eventually causing FPC fractures. To mitigate this, we utilize finite element analysis (FEA) to simulate the FPC's movement and stress distribution. This allows us to optimize the design, such as rounding sharp corners, applying protective coatings, and adjusting the FPC's routing path to minimize friction and stress concentrations.

Material Selection and Durability

The choice of materials significantly impacts FPC lifespan. High - quality Polyimide (PI) substrates are commonly used for their excellent thermal stability, chemical resistance, and mechanical flexibility. At our manufacturing base, we source top - tier materials and conduct rigorous quality control tests, including tensile strength, elongation, and dielectric constant measurements. Additionally, the selection of conductive materials, such as copper foils with superior conductivity and corrosion resistance, plays a vital role in ensuring long - term electrical performance.

Shenzhen Huaruixin Electronics Co., Ltd. - Your Trusted Partner

As a professional ODM/OEM manufacturer with a large - scale production facility, Shenzhen Huaruixin Electronics Co., Ltd. has been at the forefront of FPC innovation. Our team of experienced engineers continuously researches and develops advanced manufacturing techniques and design strategies to address the challenges related to FPC lifespan.

If you're interested in learning more about FPC design, manufacturing, or have specific project requirements, we invite you to visit our website at www.hrxfpc.com. For detailed inquiries or to start a technical discussion, please email us at sales@hrxfpc.com. Let's collaborate to drive the evolution of FPC technology and create more reliable, high - performance electronic products.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP