Search

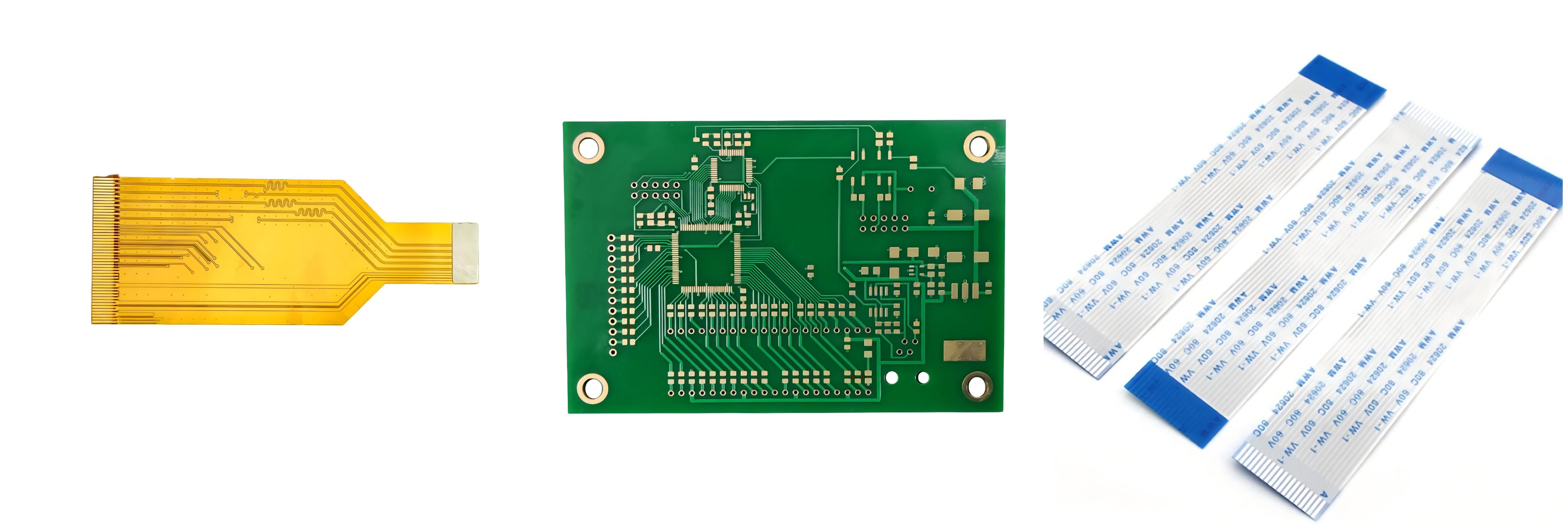

FPC, PCB, and FFC: In - Depth Analysis, Key Differences, and Diverse Applications

- May 10,2025

-

Share

In the rapidly advancing realm of electronics manufacturing, Flexible Printed Circuits (FPC), Printed Circuit Boards (PCB), and Flexible Flat Cables (FFC) stand as fundamental components, each with its unique attributes and applications. As a globally recognized ODM/OEM manufacturer, Shenzhen Huaruixin Electronics Co., Ltd. specializes in the design, development, and production of FPC, PCB, and Rigid - Flex Printed Boards, leveraging our large - scale manufacturing bases and cutting - edge technology.

1. Structural and Material Distinctions

1.1 FPC (Flexible Printed Circuits)

FPCs are engineered with high - performance flexible substrates, predominantly polyimide (PI) or polyethylene terephthalate (PET). These materials endow FPCs with exceptional bendability, enabling them to withstand repeated flexing without compromising electrical integrity. The conductive traces on FPCs are fabricated through advanced photolithography and etching processes, achieving fine - pitch geometries down to a few micrometers. Multi - layer FPCs often incorporate blind and buried vias, high - density interconnect (HDI) technology, and advanced laminate materials for enhanced signal integrity and reduced electromagnetic interference (EMI). This makes FPCs ideal for applications requiring three - dimensional routing, such as in wearable devices, medical electronics, and aerospace equipment.

1.2 PCB (Printed Circuit Boards)

PCBs typically utilize rigid substrates, including FR - 4 fiberglass epoxy laminate, which offers excellent mechanical stability and electrical insulation. The copper - clad layers are processed using standard PCB manufacturing techniques, including through - hole plating, surface - mount technology (SMT), and via - in - pad (VIP) designs. Multilayer PCBs, especially those with high - layer counts, often employ sequential lamination and backdrilling to optimize signal performance. Their rigidity makes them suitable for high - power applications, industrial control systems, and server - grade motherboards where stability and durability are paramount.

1.3 FFC (Flexible Flat Cables)

FFCs consist of flat, parallel conductors encased between two layers of insulating film, usually polyester or polyimide. The conductors are typically made of tinned copper and are bonded to the films using thermal compression or adhesive lamination. While FFCs offer some flexibility, their bend radius is generally larger compared to FPCs, limiting their use to simpler, two - dimensional routing applications. They are cost - effective solutions for short - distance, low - frequency signal transmission, such as in consumer electronics and office automation equipment.

2. Manufacturing Process Complexities

2.1 FPC Manufacturing

The fabrication of FPCs involves a series of intricate processes. After substrate preparation, photolithography is used to transfer the circuit pattern onto the copper - clad layer. The etching process then removes the unwanted copper, creating precise conductive traces. For multilayer FPCs, processes such as layer alignment, lamination, and via formation are critical. Shenzhen Huaruixin Electronics Co., Ltd. employs state - of - the - art equipment, including laser drilling machines for microvias and automated optical inspection (AOI) systems, to ensure the highest quality and reliability of our FPC products. Our expertise in Flex - Rigid technology further allows us to combine the flexibility of FPCs with the rigidity of PCBs, meeting the complex requirements of modern electronics.

2.2 PCB Manufacturing

PCB manufacturing follows a well - established process flow. It begins with material cutting and drilling, followed by electroless copper plating to create a conductive base for subsequent processes. The circuit pattern is then transferred using photoresist, and the copper is etched to form the desired traces. Surface finishing processes, such as electroless nickel immersion gold (ENIG) or organic solderability preservative (OSP), are applied to enhance the PCB's solderability and corrosion resistance. Our large - scale manufacturing facilities are equipped to handle high - volume production, ensuring fast turnaround times and competitive pricing.

2.3 FFC Manufacturing

FFC production is relatively streamlined. The flat conductors are first aligned and bonded to the insulating films, and then the assembled cable is cut to the required length. Quality control focuses on ensuring the integrity of the conductor - film bond and the uniformity of the cable thickness. Our company's automated production lines enable efficient FFC manufacturing, maintaining consistent quality while meeting tight production schedules.

3. Application Landscape

3.1 FPC Applications

FPCs have carved a niche in numerous high - tech applications. In the smartphone industry, FPCs are essential for connecting components such as the display, camera, fingerprint sensor, and battery, enabling the slim and compact designs consumers demand. In the automotive sector, FPCs are used in advanced driver - assistance systems (ADAS), infotainment systems, and electric vehicle battery management systems due to their ability to withstand harsh environmental conditions. Additionally, in the medical field, FPCs are utilized in minimally invasive surgical devices and wearable health monitors, where flexibility and biocompatibility are crucial. Shenzhen Huaruixin Electronics Co., Ltd. has extensive experience in providing customized FPC solutions for these diverse applications, leveraging our R & D capabilities to meet specific customer requirements.

3.2 PCB Applications

PCBs are ubiquitous in the electronics industry. From consumer electronics like smart TVs and gaming consoles to industrial applications such as robotics and automation systems, PCBs serve as the backbone for electronic circuitry. In the telecommunications sector, high - performance PCBs are used in 5G base stations and network routers to handle high - speed data transmission. Our company offers a wide range of PCB solutions, from standard single - layer boards to complex high - density interconnect (HDI) boards, catering to the needs of different industries.

3.3 FFC Applications

FFCs are commonly found in applications where simplicity and cost - effectiveness are prioritized. They are widely used in computer peripherals, such as keyboard and mouse connections, as well as in household appliances like printers and scanners. Their flat design makes them easy to route in confined spaces, and their low - cost production makes them an attractive option for mass - market products.

In conclusion, FPCs, PCBs, and FFCs each have their own unique advantages and are indispensable in the electronics industry. Shenzhen Huaruixin Electronics Co., Ltd., with our deep - rooted expertise and comprehensive manufacturing capabilities, is dedicated to providing high - quality products and innovative solutions. We invite industry peers, potential customers, and technology enthusiasts to visit our website at www.hrxfpc.com for more information or contact us at sales@hrxfpc.com. Let's collaborate, share insights, and drive the future of electronics manufacturing together.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP