Search

Essential Considerations in Power Supply FPC Design: A Comprehensive Guide

- May 12,2025

-

Share

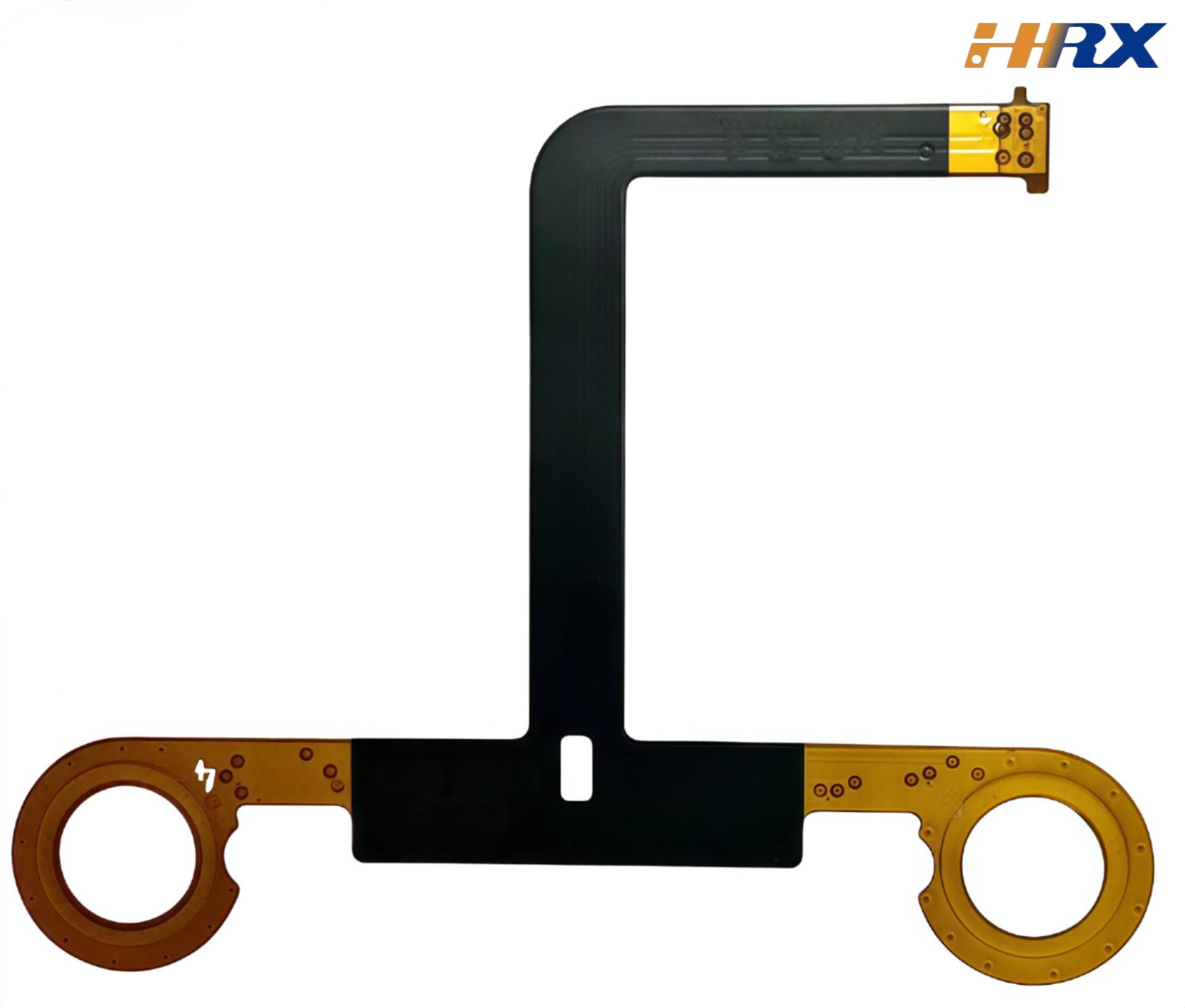

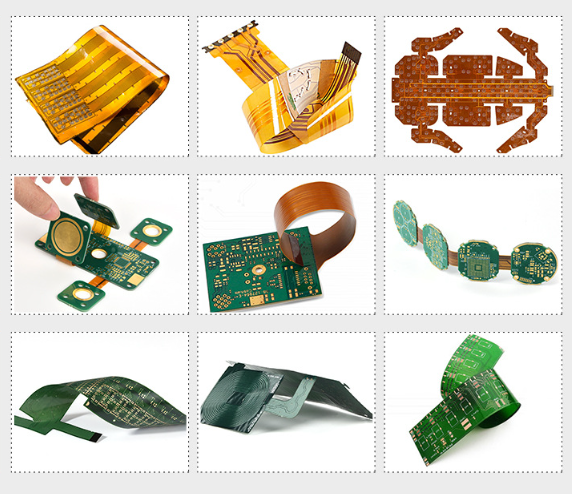

In the dynamic realm of power engineering, the design of Flexible Printed Circuits (FPCs) stands as a linchpin for the optimal performance of power supply systems. As a leading global ODM/OEM manufacturer of FPC, PCB, and Rigid - Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. has amassed profound expertise in this field.

1. Strategic Trace Routing for Signal Integrity

The routing of traces in FPCs for power supplies is a meticulous process that demands a deep understanding of signal characteristics. In power supply circuitry, diverse signal types such as input/output, AC/DC, high - power/low - power, high - frequency/low - frequency, and high - voltage/low - voltage signals coexist. To ensure signal integrity and minimize crosstalk, these signals should follow a linear or separated routing pattern. A linear route is the most desirable as it reduces electromagnetic interference (EMI) and signal coupling. However, due to spatial and component layout constraints, achieving a perfectly straight - line route is often challenging. In such cases, isolation barriers, like grounded copper pours or shielding layers, can be employed to mitigate interference.

For example, in a high - frequency switching power supply, separating the high - current DC paths from the low - level control signal paths using differential routing techniques and isolation trenches can significantly enhance the overall performance. It's important to note that while the routing requirements for DC, small - signal, and low - voltage FPC designs are relatively less stringent, a well - planned route remains crucial for optimal functionality. At Shenzhen Huaruixin Electronics, our engineers leverage advanced design tools and simulation software to create customized trace routing strategies, ensuring that each FPC design meets the highest standards of signal integrity and performance.

2. Precise Grounding Point Selection for Noise Suppression

Grounding is a fundamental aspect of FPC design that significantly impacts the stability and noise performance of power supply systems. In FPCs, the concept of a common ground point is highly emphasized. For instance, in a multi - stage amplifier circuit, all ground lines should converge at a single point before connecting to the main ground plane. This approach helps to eliminate ground loops, which can introduce unwanted noise and distortion into the circuit.

However, in practical designs, achieving a perfect common ground can be challenging due to various factors such as component placement and trace length limitations. To address this, our team at Shenzhen Huaruixin Electronics utilizes advanced grounding techniques, including star - point grounding and ground - plane stitching. By carefully analyzing the current flow and signal characteristics, we can optimize the grounding layout to minimize noise and improve the overall reliability of the FPC. Additionally, the use of via stitching in the ground plane can enhance the electrical conductivity and reduce the impedance of the grounding network, further improving the noise suppression capabilities.

3. Optimal Placement of Power Filtering and Decoupling Capacitors

Power filtering and decoupling capacitors play a pivotal role in maintaining the stability and performance of power supply FPCs. These capacitors are designed to filter out high - frequency noise and provide local energy storage for switching devices, such as MOSFETs and gate drivers. To ensure their effectiveness, they must be placed in close proximity to the components they serve. The closer the capacitor is to the power - consuming component, the more efficiently it can respond to sudden changes in current demand, reducing voltage fluctuations and noise.

At Shenzhen Huaruixin Electronics, we follow a rigorous design process for capacitor placement. Our engineers use circuit simulation tools to analyze the frequency response of the power supply and determine the optimal locations for each capacitor. In addition to traditional electrolytic and ceramic capacitors, we also utilize advanced capacitor technologies, such as tantalum capacitors and multi - layer ceramic capacitors (MLCCs), to meet the specific requirements of different power supply applications. By carefully selecting and placing these capacitors, we can significantly improve the power integrity and stability of the FPC.

4. Trace Design and Via Optimization for Reliability

Trace design in FPCs for power supplies requires a combination of technical expertise and attention to detail. When it comes to trace width, the principle is to use the widest possible trace without sacrificing space constraints. For high - voltage and high - frequency traces, smooth curves and rounded corners should be used instead of sharp right - angles. Sharp corners can cause signal reflections and electromagnetic radiation, which can degrade the performance of the power supply and interfere with other circuits.

In addition to trace width and shape, the size and placement of vias are also critical factors. Vias are used to connect different layers of the FPC, and improper via sizing can lead to electrical and mechanical issues. At Shenzhen Huaruixin Electronics, we use advanced design software to optimize the via size and placement, ensuring that they provide a reliable electrical connection while minimizing the impact on the mechanical strength of the FPC. We also pay close attention to the pad - to - via ratio, as an improper ratio can cause pad lifting or soldering problems during the manufacturing process.

5. Via Quantity, Soldering Point Density, and Manufacturability

The design of FPCs for power supplies must also consider manufacturability factors. An excessive number of vias can increase the complexity of the manufacturing process and the risk of defects, such as open circuits or short circuits. Therefore, it's important to minimize the number of vias while still maintaining the required electrical connectivity.

Similarly, the density of soldering points and parallel traces can also impact the manufacturability of the FPC. High - density soldering points can make manual soldering difficult, while closely spaced parallel traces can increase the risk of short circuits during the soldering process. At Shenzhen Huaruixin Electronics, our design team works closely with the manufacturing department to ensure that the FPC design is optimized for both performance and manufacturability. We use Design for Manufacturing (DFM) principles to identify and address potential manufacturing issues early in the design process, reducing production costs and improving the overall quality of the FPC.

Shenzhen Huaruixin Electronics Co., Ltd. is dedicated to providing high - quality FPC, PCB, and Rigid - Flex Printed Board solutions for power supply applications. Our team of experienced engineers and designers is committed to delivering innovative and reliable designs that meet the evolving needs of our customers.

We invite you to explore our website at www.hrxfpc.com to learn more about our products and services. For inquiries or to discuss your specific project requirements, please contact us at sales@hrxfpc.com. Let's collaborate and drive the advancement of FPC design in the power supply industry together.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP