Search

Emerging Trends in FPC Technology for AI - Powered Cameras

- May 19,2025

-

Share

In the current technological landscape, the convergence of artificial intelligence (AI) and camera technology has given rise to a new generation of highly intelligent and efficient imaging systems. These AI - powered cameras are transforming diverse industries, including surveillance, security, healthcare, automotive, and more. At the core of these advanced camera systems lies Flexible Printed Circuit (FPC) technology, which is indispensable for ensuring seamless operation and superior performance in AI - powered camera applications.

The Ascendancy of AI - Powered Cameras

AI - powered cameras represent a significant leap forward in imaging technology. Equipped with state - of - the - art machine learning algorithms and advanced computer vision capabilities, they can analyze and interpret visual data in real - time. In the realm of surveillance, these cameras can accurately identify and track individuals, detect suspicious activities, and recognize objects and patterns with remarkable precision. In the automotive sector, they are pivotal components in driver assistance systems, facilitating functions such as lane departure warning, collision avoidance, and autonomous driving.

The exponential growth in the demand for AI - powered cameras, driven by the escalating need for intelligent visual data analysis across various sectors, has spurred manufacturers to continuously seek ways to enhance camera performance and functionality. In this pursuit, FPC technology has emerged as a key enabler, offering solutions that are crucial for the development of next - generation AI - camera systems.

FPC Technology: A Comprehensive Overview

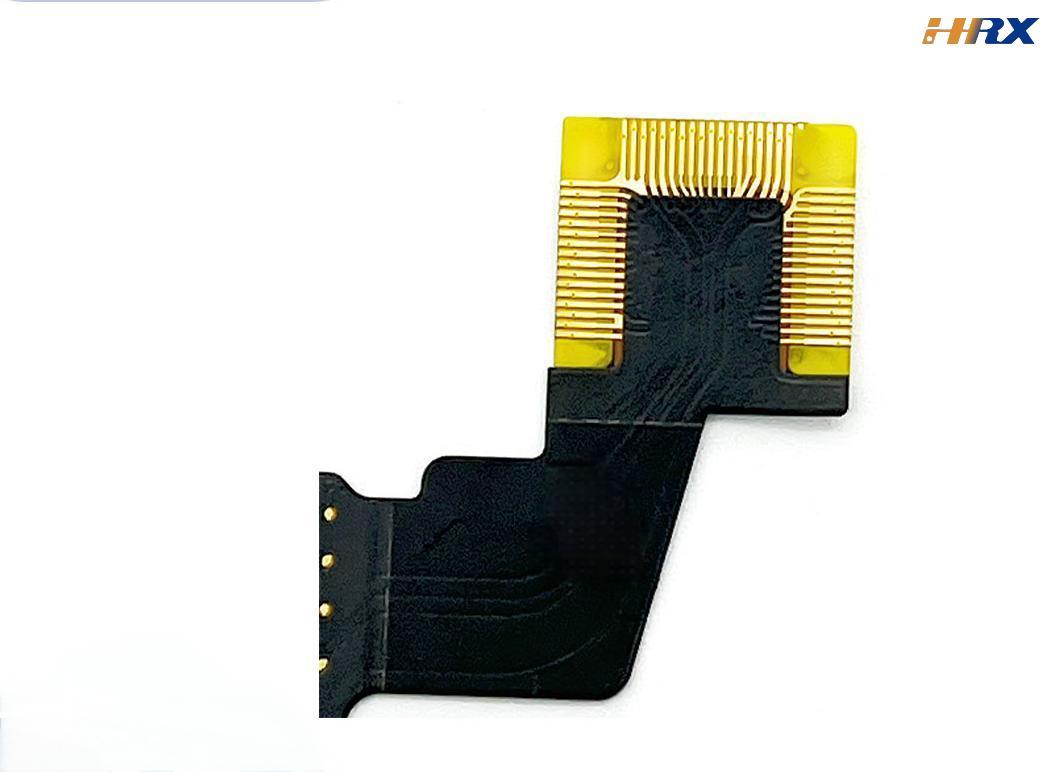

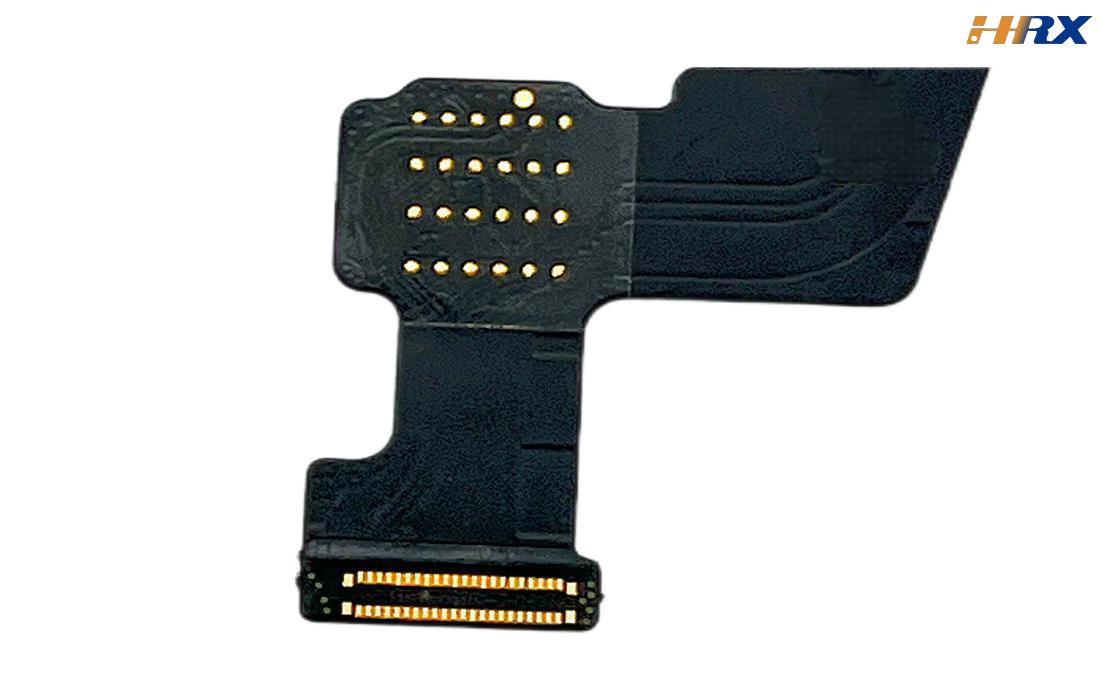

Flexible Printed Circuits (FPCs) are thin, lightweight, and highly flexible electronic circuits fabricated by printing conductive traces on flexible substrates, typically polyimide or polyester. Their ability to withstand bending, twisting, and folding without damage makes them the ideal choice for applications where space constraints are severe or where components require flexibility.

Shenzhen Huaruixin Electronics Co., Ltd., a globally recognized leader in the design, development, and large - scale manufacturing of FPCs, PCBs, and FlexRigid PCBs, offers comprehensive ODM/OEM production services. With extensive experience across multiple industries, including the rapidly evolving field of AI - powered cameras, the company has a proven track record of delivering high - quality FPC solutions. Leveraging its in - depth expertise in FPC technology, Shenzhen Huaruixin Electronics Co., Ltd. can customize circuits to meet the exacting requirements of AI - camera manufacturers, ensuring optimal performance, reliability, and compatibility with advanced camera systems.

Emerging Trends in FPC Technology for AI - Powered Cameras

1. Miniaturization and High - Density Integration

As AI - powered cameras evolve towards greater compactness and enhanced functionality, there is an urgent demand for FPCs that support miniaturization while maintaining high - density interconnects. FPC manufacturers are investing in cutting - edge manufacturing processes, such as laser direct imaging and micro - via formation, to produce circuits with ultra - fine traces and vias. This enables the integration of a greater number of components within a reduced footprint, which is particularly critical for applications like wearable cameras, miniature surveillance devices, and in - vehicle camera modules where size and weight are major design considerations.

2. Signal Integrity Enhancement

The operation of AI - powered cameras hinges on the rapid and accurate transmission of vast amounts of data, necessitating FPCs with exceptional signal integrity. To meet this requirement, FPC technology is undergoing continuous evolution. Advanced materials with low dielectric constants and high - frequency performance, along with innovative design techniques like differential signaling and impedance matching, are being employed. These advancements effectively mitigate signal loss, crosstalk, and electromagnetic interference (EMI), ensuring clean and stable signal transmission even at high frequencies. This is of utmost importance for applications involving high - resolution image sensors, high - speed data interfaces (such as LVDS and MIPI), and complex camera processing units.

3. Augmented Flexibility and Robust Durability

AI - powered cameras often operate in challenging environments, especially in automotive, industrial, and outdoor applications, where they are exposed to mechanical stresses, temperature fluctuations, and environmental contaminants. Consequently, FPCs must exhibit enhanced flexibility and durability. Manufacturers are developing FPCs with extended flex life, achieved through optimized material compositions and advanced manufacturing processes. Additionally, surface coatings and encapsulation techniques are being applied to protect FPCs from moisture, dust, chemicals, and mechanical abrasion, ensuring long - term reliability and performance in harsh operating conditions.

4. Embedded Component Integration

A notable trend in FPC technology is the integration of embedded components, including sensors, passive components (capacitors, resistors), and even active components, directly onto the FPC substrate. This integration strategy significantly reduces the overall size and weight of the camera system, simplifies the assembly process, and minimizes the number of interconnections, thereby enhancing system reliability and performance. For example, in medical imaging AI - cameras, FPCs with integrated physiological sensors can enable real - time monitoring and data collection, all within a compact and flexible circuit design.

5. Advanced Manufacturing Paradigms

The production of FPCs for AI - powered cameras is witnessing a paradigm shift with the adoption of advanced manufacturing techniques. Technologies such as laser ablation for precise pattern formation, 3D additive manufacturing for creating complex geometries and multi - layer structures, and nano - manufacturing for ultra - fine feature fabrication are becoming increasingly prevalent. Shenzhen Huaruixin Electronics Co., Ltd., with its large - scale manufacturing infrastructure and technological prowess, is well - equipped to harness these advanced techniques. By leveraging these capabilities, the company can produce high - quality FPCs that meet the stringent requirements of AI - camera manufacturers, driving innovation in the field of AI - powered imaging systems.

The Indispensable Role of FPCs in AI - Powered Cameras

FPCs act as the neural network of AI - powered cameras, facilitating seamless connectivity between critical components such as image sensors, lenses, processors, and memory modules. They ensure the efficient transfer of electrical signals and data, which is essential for the smooth operation of the entire camera system. The inherent flexibility of FPCs enables innovative and space - optimized designs, allowing manufacturers to integrate more functionality into compact form factors. For instance, in drone - mounted AI - cameras, FPCs can be contoured to fit the drone's aerodynamic structure, connecting all components while minimizing weight and maximizing space utilization.

Future Prospects

The future of FPC technology in AI - powered cameras is rife with opportunities. As AI technology continues to advance and new applications emerge, the demand for high - performance, reliable, and flexible FPCs will only intensify. Companies like Shenzhen Huaruixin Electronics Co., Ltd., at the forefront of FPC design and manufacturing, are poised to drive further innovation. With continuous research and development, we can anticipate even more sophisticated FPC solutions that will push the boundaries of what AI - powered cameras can achieve, whether it's improving the accuracy of biometric recognition in security systems or enabling more advanced autonomous navigation features in vehicles.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP