Search

Common Issues & Solutions in OSP Treatment for FPC/PCB: A Comprehensive Guide

- Sep 30,2025

-

Share

In the manufacturing of Flexible Printed Circuits (FPC) and Printed Circuit Boards (PCB), OSP (Organic Solderability Preservatives) treatment is a critical surface finishing process that safeguards copper surfaces, preserves solderability, and ensures long-term reliability. However, OSP film quality, solderability, and stability are highly susceptible to variables like FPC pre-treatment cleanliness, OSP film formation parameters, and post-treatment environmental conditions.

I. Abnormal OSP Film Appearance in FPC/PCB (Critical for Welding Reliability)

Abnormal film appearance is the most frequent challenge in OSP treatment for FPC and PCB, directly impacting subsequent FPC soldering processes and end-product performance. Common manifestations include spots, skip plating, discoloration, and uneven thickness, often stemming from pre-treatment residues, uncontrolled film formation, or bath contamination.

1. White/Gray Spots on OSP Film

Core Causes:

Inadequate rinsing post-pre-treatment: Residues of FPC micro-etching solutions (e.g., ammonium persulfate) or degreasing agents react with the OSP film to form salt precipitates.

Poor rinsing water quality: Impurities like chloride/calcium ions in water react with FPC copper surfaces or OSP agents, creating visible spots.

Delayed drying: Moisture retention on FPC copper surfaces post-rinsing leads to oxidation (forming Cu₂O) before OSP film formation, resulting in gray spots.

Targeted Solutions:

Optimize FPC rinsing workflows: Extend the duration of secondary and tertiary rinses to 1.5–2 minutes, combine spray + immersion rinsing for thoroughness, and monitor post-rinse conductivity to ≤5μS/cm (critical for FPC surface purity).

Use high-purity deionized water: Ensure water resistivity ≥18MΩ・cm for rinsing, and schedule regular replacement of FPC rinse tank water to eliminate impurity buildup.

Accelerate FPC drying: Increase hot-air drying temperature to 75–85℃ and reduce transfer time from rinsing to drying to ≤30 seconds—vital for preventing oxidation on flexible copper clad laminates (FCCL).

2. Local Skip Plating on FPC/PCB (Exposed Copper or Ultra-Thin Film)

Core Causes:

Incomplete removal of contaminants on FPC copper: Residual fingerprints, release agents, or oxide layers (from FPC manufacturing) persist post-degreasing; insufficient micro-etching (<0.5μm) prevents OSP agents from bonding with copper.

Uneven OSP bath concentration: Poor circulation (e.g., faulty stirrers) leads to low OSP agent concentration at FPC edges, corners, or flexible folds, inhibiting film formation.

Solder mask residue on FPC: Overflow of FPC solder mask ink onto copper pads covers active copper sites, blocking OSP-chelation reactions.

Targeted Solutions:

Strengthen FPC pre-treatment:

Adjust degreasing agent concentration to the upper limit of its formula and extend degreasing time to 2–3 minutes to eliminate organic residues on FPC.

Verify micro-etching solution concentration and ensure an etching depth of 0.8–1.2μm (use an etching tester) to remove oxide layers without damaging FPC trace integrity.

Maintain OSP bath for FPC production:

Activate bath stirrers to ensure a flow rate ≥0.5m/s, preventing sediment buildup at the tank bottom (critical for uniform film on FPC’s flexible areas).

Test OSP bath concentration every 2 hours and replenish masterbatch promptly to maintain optimal levels for FPC/PCB processing.

Pre-clean FPC solder mask: Add a dedicated "solder mask cleaning step" before OSP—use a weak solvent to wipe FPC copper pads, ensuring no ink residue (essential for FPC pad solderability).

3. Abnormal OSP Film Color (Too Dark: Brown; Too Light: Colorless)

Core Causes:

Too Dark: Excessively long OSP film formation time (>3 minutes) or high bath temperature (>55℃) leads to ultra-thick films (>0.5μm) on FPC/PCB, which oxidize to a brown hue.

Too Light: Insufficient reaction time (<1 minute), low bath temperature (<40℃), or acidic OSP bath (pH <8) results in thin films (<0.2μm) that fail to protect FPC copper.

Targeted Solutions:

Calibrate OSP film formation parameters for FPC:

For brown films: Reduce bath temperature to 45–50℃, shorten formation time to 1.5–2 minutes, and monitor film thickness to 0.3–0.4μm (ideal for FPC’s flexibility and solderability).

For colorless films: Increase bath temperature to 50–55℃, extend formation time to 2–2.5 minutes, and adjust pH to 8.5–9.5 with ammonia water (optimizes chelation for FPC copper).

Regularly calibrate equipment: Use a precision thermometer to verify OSP bath temperature (error ≤±1℃) and a pH meter to confirm bath acidity (error ≤±0.1)—critical for consistent FPC film quality.

4. Sticky/Wrinkled OSP Film on FPC/PCB

Core Causes:

Incomplete post-drying: Residual moisture on FPC/PCB post-rinsing prevents full OSP film curing, causing stickiness.

Aging OSP bath: Extended use (>10 days) leads to copper ion buildup (Cu²⁺ >500ppm), weakening film structure on FPC.

Premature stacking: Dried FPC/PCB are stacked before cooling to room temperature (>40℃), causing film adhesion and wrinkling (especially problematic for flexible FPC).

Targeted Solutions:

Optimize FPC post-drying: Increase secondary drying temperature to 80–90℃, extend time to 3–4 minutes, and use a moisture tester to ensure FPC/PCB moisture content ≤0.05% (prevents stickiness).

Replace OSP bath for FPC production: When copper ion levels exceed standards, fully drain the old bath, clean the tank thoroughly, and refill with fresh OSP agent—avoids structural defects in FPC films.

Implement controlled FPC cooling: Place dried FPC/PCB on a dedicated cooling rack and allow natural cooling to 25–30℃ before stacking. Limit stack height to ≤10 pieces to prevent wrinkling (preserves FPC’s flexible properties).

II. OSP Solderability Failure in FPC/PCB (Threatens Assembly Quality)

The primary purpose of OSP treatment is to maintain FPC/PCB copper solderability. Failures like solder non-wetting, cold joints, or voids often stem from film defects or pre-welding degradation.

1. Solder Non-Wetting (FPC/PCB Copper Rejects Solder)

Core Causes:

Ultra-thick OSP film (>0.5μm): High temperatures during FPC reflow soldering cannot fully decompose the film, blocking solder-copper contact.

Film oxidation: Extended FPC/PCB storage (>6 months) or high humidity (>60%) causes OSP films to absorb moisture and degrade.

Insufficient soldering temperature: Reflow peak temperatures <240℃ (below the requirement for lead-free FPC soldering, 240–260℃) leave film residues.

Targeted Solutions:

Control OSP film thickness for FPC: Use an ellipsometer to monitor thickness in real time, ensuring it stays within 0.2–0.5μm (balances protection and solderability for FPC).

Optimize FPC/PCB storage:

Vacuum-package OSP-treated FPC/PCB within 24 hours (include silica gel desiccant) to isolate moisture.

Maintain storage conditions at 20–25℃ and 40–50% humidity; limit shelf life to 6 months to prevent film oxidation.

Adjust FPC soldering parameters: Increase reflow peak temperature to 250–260℃ and hold for 10–15 seconds—ensures complete OSP film decomposition and reliable FPC solder joint formation.

2. Cold Solder Joints/Voids in FPC/PCB

Core Causes:

Poor OSP film adhesion: Uneven micro-etching on FPC copper (roughness <0.3μm) weakens film bonding; film peeling during soldering releases gas, forming voids.

Contaminated OSP bath: Oil or dust in the bath becomes encapsulated in FPC/PCB films; these impurities volatilize during soldering, creating voids.

Incompatible flux: Low-activity flux fails to remove residual OSP film fragments, leading to cold joints on FPC pads.

Targeted Solutions:

Optimize FPC micro-etching: Ensure an etching depth of 1.0–1.5μm to achieve a copper surface roughness of Ra=0.3–0.5μm (use a roughness meter)—enhances film adhesion for FPC.

Purify OSP bath for FPC production:

Install filter cotton at the bath inlet to trap impurities (e.g., FPC debris) before they enter the solution.

Replace bath filter cartridges (10μm precision) weekly to maintain clean conditions for FPC/PCB film formation.

Select compatible flux for OSP: Use ROHS-compliant medium-activity flux (test compatibility with OSP films in advance) to fully remove residues and ensure strong FPC solder joints.

III. Unstable OSP Film Performance in FPC/PCB (Affects Long-Term Reliability)

Unstable film performance—characterized by poor corrosion resistance and peeling—endangers FPC/PCB service life, often due to incomplete film formation or improper post-treatment.

1. Poor Film Corrosion Resistance (Fails Salt Spray Tests)

Core Causes:

Suboptimal OSP agent selection: Low-purity agents (e.g., benzotriazoles) offer weaker corrosion protection than imidazole-based OSP agents (ideal for FPC/PCB).

Incomplete chelation: Acidic OSP baths (pH <8) prevent full reaction between copper and OSP agents, resulting in porous films on FPC.

Residual OSP agent: Post-rinsing residues on FPC/PCB absorb moisture during storage, accelerating film aging.

Targeted Solutions:

Upgrade to high-performance OSP agents: Use pure imidazole-based agents (e.g., 2-phenylimidazole) for FPC/PCB—they deliver superior salt spray resistance compared to traditional alternatives.

Stabilize OSP bath pH: Use ammonia water to maintain a pH of 8.5–9.5 (test every 2 hours) to ensure complete chelation and dense film formation on FPC.

Enhance FPC post-rinsing: Add a "pure water spray step" (pressure 0.2–0.3MPa) to post-treatment; wipe FPC/PCB surfaces with alcohol post-rinsing to confirm no residue (critical for corrosion resistance).

2. OSP Film Peeling (Fails Adhesion Tests)

Core Causes:

Insufficient FPC pre-activation: Skipping activation leaves few active sites on copper surfaces, weakening film bonding for FPC.

Rapid cooling: Dried FPC/PCB are exposed to cold air (temperature difference >30℃), causing film peeling via thermal expansion/contraction.

Excessive stacking pressure: Stack weights >5kg damage films on FPC (especially fragile flexible areas), leading to peeling.

Targeted Solutions:

Add FPC activation step: Fill the activation bath with 0.5% dilute sulfuric acid (pH=2–3) and process FPC for 1–1.5 minutes—boosts copper surface activity for stronger film adhesion.

Implement gradual cooling: Place dried FPC/PCB in a "slow-cooling box" (50–60℃) and reduce temperature at a rate ≤5℃/minute—prevents thermal stress on FPC films.

Control FPC stacking pressure: Use specialized racks for FPC/PCB and limit stack weight to ≤3kg—avoids mechanical damage to flexible films.

IV. Preventive Measures for OSP Treatment in FPC/PCB Production (Reduce Defects Proactively)

Proactive maintenance and process control are key to minimizing OSP issues in FPC/PCB manufacturing—critical for optimizing productivity and Google search-relevant metrics like "FPC OSP yield rate."

1. Regular Equipment & Bath Maintenance

Daily Tasks: Test concentration, pH, and temperature of FPC degreasing agents, micro-etching solutions, and OSP baths; record data to track trends.

Weekly Tasks: Clean FPC/PCB treatment tanks (remove sediment from walls), replace rinse tank filters, and calibrate instruments (pH meters, thermometers, film thickness gauges) for accuracy.

Monthly Tasks: Fully replace OSP baths (even if concentration is adequate)—copper ion buildup degrades film quality for FPC/PCB over time.

2. Strict FPC/PCB Pre-Treatment Quality Control

Conduct water film tests post-pre-treatment: Sprinkle water on FPC/PCB copper surfaces—continuous water film retention (≥30 seconds) confirms no oil residue.

Inspect FPC copper via 200x microscope post-micro-etching: Ensure no oxide spots, burrs, or uneven roughness—critical for uniform OSP film formation.

3. Standardized FPC/PCB Storage & Transportation

Vacuum-package finished OSP-treated FPC/PCB with silica gel desiccant (1x 5g pack per 10 pieces) to prevent moisture damage.

Avoid severe vibration during transportation (protects FPC’s flexible structure and OSP films); maintain ambient conditions at 5–35℃ and ≤60% humidity.

Partner with Shenzhen Huaruixin Electronics for Reliable FPC/PCB OSP Solutions

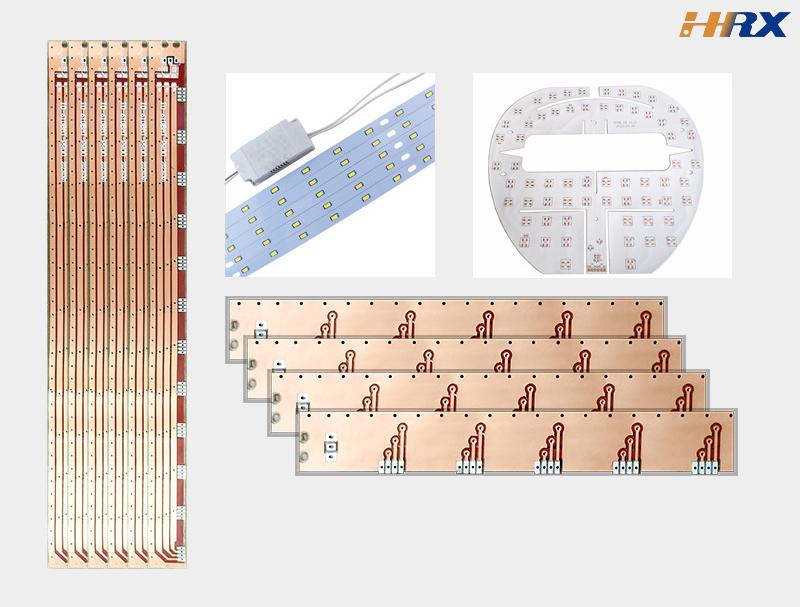

As a global leader in FPC ODM/OEM manufacturing and rigid-flex PCB production, Shenzhen Huaruixin Electronics Co., Ltd. leverages state-of-the-art facilities and strict quality management systems to deliver high-performance OSP-treated FPC/PCB. Our certifications—GB/T19001-2016/ISO 9001:2015, IAF international accreditation, and CNAS national accreditation—ensure consistent quality for applications like consumer electronics, automotive, and medical devices.

For customized FPC OSP treatment solutions, project inquiries, or industry insights (e.g., "FPC surface finishing best practices"), visit our website: www.hrxfpc.com or email our team at sales@hrxfpc.com. We’re committed to helping you optimize FPC/PCB production efficiency and product reliability.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP