Search

Breakthroughs and Characteristics of LDI Technology in FPC Applications

- Jun 25,2025

-

Share

In the dynamic and rapidly advancing realm of electronics manufacturing, Flexible Printed Circuits (FPCs) have firmly established themselves as an essential component, thanks to their inherent flexibility, compact form factor, and lightweight attributes. Among the plethora of manufacturing methodologies, Laser Direct Imaging (LDI) technology has emerged as a revolutionary force, driving significant breakthroughs in FPC fabrication. This blog post aims to comprehensively explore the application breakthroughs and distinctive characteristics of LDI technology in FPCs, while also highlighting the pivotal role of Shenzhen Huaruixin Electronics Co., Ltd., a globally recognized ODM/OEM manufacturer specializing in FPCs, PCBs, and Rigid - Flex Printed Boards, in harnessing this cutting - edge technology.

Application Breakthroughs of LDI Technology in FPCs

Enhanced Precision and Miniaturization for High - Density Interconnect FPCs

One of the most notable breakthroughs of LDI technology in FPC manufacturing lies in its unparalleled ability to achieve ultra - high precision. In the era of continuous miniaturization of electronic devices, traditional photolithography methods often fall short in meeting the increasingly exacting requirements for fine - pitch patterns. LDI technology, by contrast, employs a highly focused laser beam to directly expose the photoresist layer on the FPC substrate. This direct exposure mechanism enables the fabrication of intricate circuit patterns with line widths and spaces reaching down to a few micrometers, facilitating the development of high - density interconnect (HDI) FPCs. For instance, in the production of state - of - the - art consumer electronics such as smartphones, tablets, and wearable devices, LDI - manufactured FPCs can accommodate more complex circuit designs within a confined space, thereby significantly enhancing the overall performance, functionality, and integration density of these devices.

Improved Production Efficiency through Streamlined Processes

LDI technology also heralds a substantial leap in production efficiency within the FPC manufacturing domain. Unlike traditional film - based exposure techniques, LDI eliminates the time - consuming and labor - intensive steps of film production, alignment, and handling. Leveraging digital design data, typically in the form of Gerber files, the laser can directly write the circuit patterns onto the FPC substrate with pinpoint accuracy, drastically reducing the number of process steps and overall production cycle time. Moreover, the continuous operation capabilities of LDI systems further augment the throughput of FPC manufacturing lines. This enhanced efficiency not only translates into cost savings but also empowers manufacturers to respond more promptly to fluctuating market demands, enabling faster product launches and improved supply chain agility.

Superior Process Control and Yield Enhancement

With LDI technology, manufacturers gain unprecedented control over the imaging process. Key laser exposure parameters, including power, scanning speed, and focal depth, can be meticulously adjusted in real - time to suit different FPC materials, substrate thicknesses, and design specifications. This precise parameter tuning helps to minimize common defects such as over - exposure, under - exposure, pattern distortion, and registration errors, thereby significantly increasing the production yield. Additionally, advanced LDI systems are often equipped with integrated real - time monitoring and feedback mechanisms. These systems can detect and correct any deviations during the exposure process, ensuring consistent quality and reliability of the fabricated FPCs.

Characteristics of LDI Technology in FPC Applications

High - Resolution Imaging for Precise Circuit Patterns

LDI technology is highly regarded for its exceptional high - resolution imaging capabilities. By utilizing a laser source with a narrow and stable wavelength range, LDI can produce sharply defined and highly detailed circuit patterns with excellent edge acuity. This high - resolution imaging is of paramount importance for FPCs employed in applications demanding high - speed data transmission, high - frequency signal processing, and advanced automotive electronics, where precise circuit geometries are crucial for optimal performance and signal integrity.

Broad Compatibility with Diverse FPC Materials

Another key characteristic of LDI technology is its extensive compatibility with a wide array of FPC materials. Whether it is polyimide (PI), which is widely used for its high - temperature resistance and mechanical flexibility, polyester (PET), or other specialized flexible substrates, LDI can effectively expose the photoresist layer, enabling the production of FPCs with diverse performance characteristics. This versatility makes LDI technology suitable for a broad spectrum of industries, ranging from consumer electronics and medical devices to aerospace and defense applications.

Digitalization and Design Flexibility for Agile Manufacturing

LDI technology embodies a high degree of digitalization, as it directly utilizes digital design data for the imaging process. This digital workflow allows for seamless design modifications and rapid prototyping. Manufacturers can easily update the FPC design, incorporate new features, or make design optimizations, and immediately proceed with production without the need for physical film changes or extensive setup adjustments. This inherent flexibility is particularly valuable in today's fast - paced electronics market, where the ability to quickly iterate designs, respond to customer feedback, and bring new products to market is essential for maintaining a competitive edge.

Shenzhen Huaruixin Electronics Co., Ltd.'s Perspective on LDI Technology

As a professional global manufacturer boasting a large - scale manufacturing facility and state - of - the - art production capabilities, Shenzhen Huaruixin Electronics Co., Ltd. has been at the vanguard of adopting advanced technologies in FPC production. The company recognizes the transformative potential of LDI technology and has fully integrated it into its manufacturing processes to elevate the quality, performance, and competitiveness of its products.

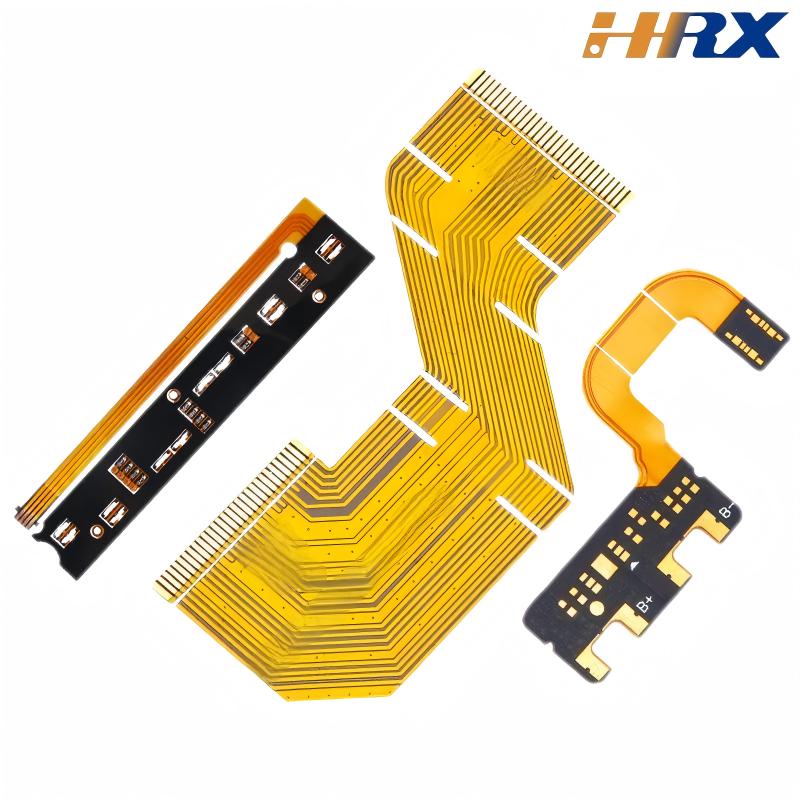

In the production of battery FPCs, a core product line of the company, LDI technology plays an indispensable role. The high precision and reliability offered by LDI - produced battery FPCs ensure stable electrical interconnections, efficient power management, and enhanced safety features, which are critical for the reliable and long - lasting operation of batteries in a wide range of applications, from portable consumer electronics to electric vehicles. By leveraging the capabilities of LDI technology, Shenzhen Huaruixin Electronics Co., Ltd. can meet the diverse and exacting requirements of customers, whether it involves high - volume production of standard battery FPCs or the development of customized solutions tailored to specific application needs.

The company's extensive expertise in FPC design, development, and manufacturing, combined with the advanced capabilities of LDI technology, positions it as a trusted partner for customers worldwide. Committed to quality excellence, technological innovation, and customer satisfaction, Shenzhen Huaruixin Electronics Co., Ltd. continues to invest in research and development to further optimize the utilization of LDI technology in FPC production, driving continuous improvement and innovation in the industry.

If you have any project requirements related to FPCs, PCBs, or Rigid - Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. stands ready to provide comprehensive solutions. As a professional manufacturer with a proven track record in handling projects of varying scales and complexities, we are equipped with the expertise, resources, and technological capabilities to meet your specific needs. Feel free to reach out to us at any time. For more in - depth industry knowledge, detailed product information, and to explore potential collaboration opportunities, please visit our website at www.hrxfpc.com or contact us via email at sales@hrxfpc.com. We look forward to the opportunity to engage in technical discussions, share insights, and collaborate with you on your next project.

In conclusion, LDI technology has ushered in significant breakthroughs in FPC applications, with its unique characteristics enabling the production of high - quality, high - performance FPCs that meet the evolving demands of modern electronics. Shenzhen Huaruixin Electronics Co., Ltd.'s strategic adoption and effective utilization of this technology underscore its commitment to excellence and leadership in the electronics manufacturing industry.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP